Ever wondered what keeps your aluminum window frames from corroding, or how your smartphone’s screen stays scratch-resistant? The answer lies in a remarkable yet often overlooked compound: aluminum oxide. While it’s rarely seen or discussed in daily conversation, this substance quietly underpins a staggering range of products and technologies that shape our modern world.

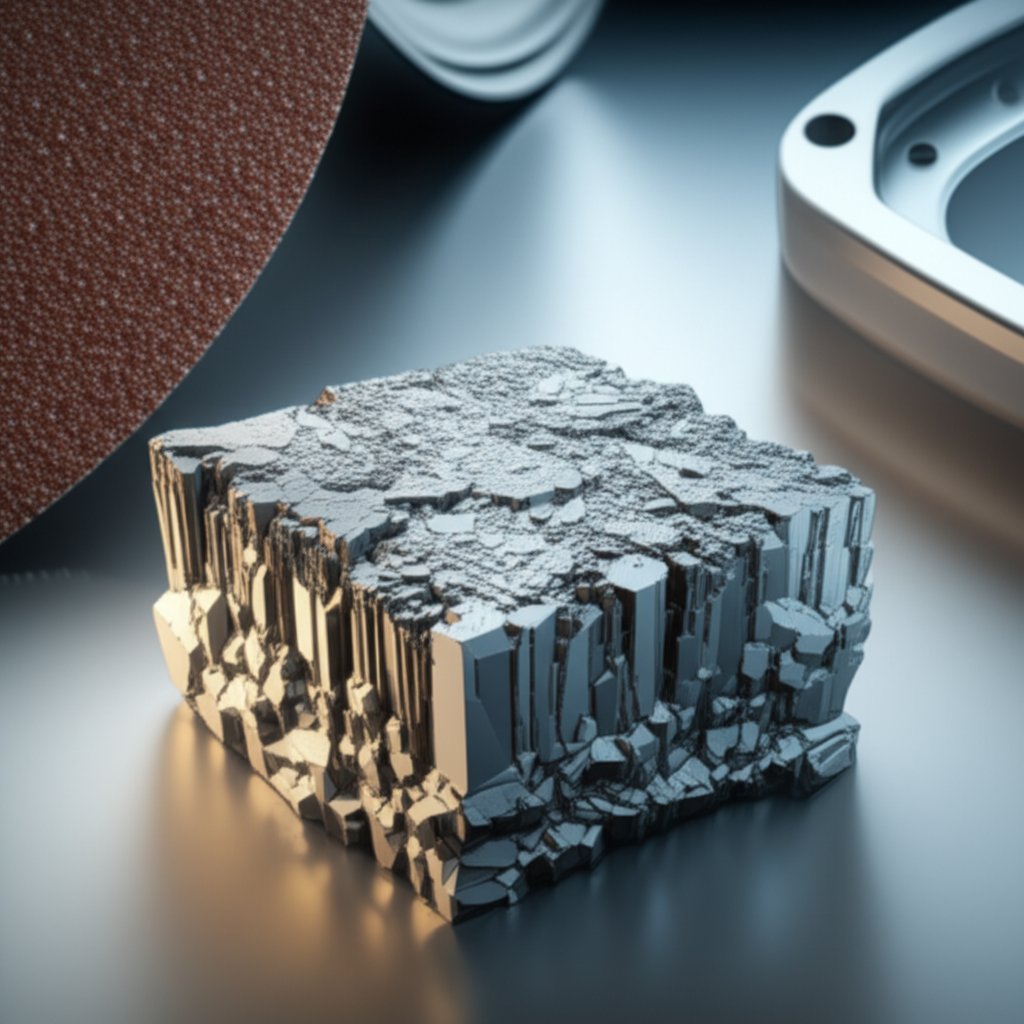

So, what is aluminum oxide? Simply put, it’s a chemical compound made up of aluminum and oxygen atoms, represented by the formula Al2O3. In nature, it occurs in several fascinating forms. The most recognized is corundum—the crystalline structure behind precious gemstones like ruby and sapphire. You’ll also find it as emery, a naturally abrasive rock, and as a fundamental component of bauxite ore—the world’s main source of aluminum metal production (Wikipedia).

This aluminum oxide compound isn’t just limited to natural deposits. It’s also produced synthetically on a massive scale, with industries refining bauxite through processes like the Bayer method to yield pure, high-quality aluminum oxide. This synthetic form is crucial for manufacturing everything from ceramics and abrasives to advanced electronics and medical implants.

In this article, you’ll discover:

Ready to explore the hidden world of aluminum oxide? Let’s dive into its foundational chemistry and see why this compound is indispensable across industries and in your daily life.

When you hear the term aluminum oxide, it might sound like something reserved for science labs or heavy industry. But did you know that this compound quietly shapes the world around you—from the sparkle of a sapphire ring to the grit of your favorite sandpaper? Let’s break down what makes aluminum oxide so foundational, and why even a simple misspelling like “aluminume oxide” can lead curious minds to this essential material.

At its core, aluminum oxide is a chemical compound formed by bonding aluminum and oxygen atoms. Its formula, Al2O3, means each molecule contains two aluminum atoms and three oxygen atoms. This simple formula hides a world of complexity, giving rise to multiple natural and synthetic forms with distinct physical characteristics (Wikipedia).

Imagine walking through a jewelry store—those dazzling rubies and sapphires owe their beauty to corundum, which is simply aluminum oxide in its purest, crystalline form. Here’s how aluminum oxide appears in nature:

So, what makes aluminum oxide stand out?

Aluminum oxide’s unique properties fuel its wide-ranging applications:

Whether you’re searching for “aluminum oxide” or the common misspelling “aluminume oxide,” you’re exploring a compound that’s as vital to modern industry as it is to the natural world. Next, we’ll dive deeper into the atomic structure and formula behind this powerhouse material, revealing how its chemistry unlocks such remarkable versatility.

Have you ever wondered why al2o3 aluminum oxide is so tough, heat-resistant, and versatile? The answer lies in its unique chemical composition and crystal structure. Let’s break down the formula of aluminum oxide and see how its atomic makeup drives its extraordinary properties.

At first glance, the formula Al2O3 might look like a jumble of letters and numbers. But it’s actually a precise way to describe the ratio and bonding of atoms in this compound. Here’s how it works:

This ratio ensures that the total positive charge from aluminum ions (+3 each) balances the total negative charge from oxygen ions (−2 each), creating a stable, electrically neutral compound.

Sounds complex? Imagine aluminum “giving away” its three outer electrons to oxygen, which “wants” two extra electrons to complete its shell. In Al2O3, each aluminum atom loses three electrons (becoming Al3+), and each oxygen atom gains two electrons (becoming O2−). The strong electrostatic attraction between these oppositely charged ions is what holds the compound together so tightly.

But the story doesn’t end with simple ions. Aluminum oxide can exist in several different crystal forms, known as polymorphs. Each polymorph has its own atomic arrangement, giving it unique properties. The most common and important is:

Other notable polymorphs include:

Here’s a quick summary for easy comparison:

| Polymorph | Structure | Main Use/Feature |

|---|---|---|

| α-Alumina (Corundum) | Hexagonal close-packed | Hardest, stable; abrasives, gemstones |

| γ-Alumina | Defective spinel | Porous; catalysts, adsorbents |

| Other forms (θ, δ, η, χ) | Transitional | Intermediate, specialty ceramics |

Curious about how chemists visualize these bonds? The Lewis dot structure is a handy tool. It shows how many valence electrons each atom has and how they’re shared or transferred. In the case of Al2O3:

This electron transfer explains why aluminum oxide is such a strong, stable, and inert compound (Study.com).

Understanding the atomic structure of Al2O3 isn’t just for chemistry class—it’s the key to appreciating its hardness, heat resistance, and industrial value. Next, we’ll see how these atomic arrangements translate into real-world physical properties that make aluminum oxide indispensable in so many fields.

When you picture a material that can withstand grinding, extreme heat, and corrosive chemicals, what comes to mind? If you guessed aluminum oxide, you’re on the right track. But what exactly gives this compound its legendary toughness and versatility? Let’s break down the key physical properties that make aluminum oxide a true workhorse in both industry and everyday life.

Imagine you’re choosing a material for a cutting tool, an electrical insulator, or a heat-resistant ceramic. You’d want to know how hard it is, how much heat it can take, and whether it resists wear and corrosion. That’s where the physical characteristics of aluminum oxide shine—literally and figuratively.

To make things easy, here’s a side-by-side comparison of the most critical properties you’ll encounter when researching or specifying aluminum oxide for a project. These values reflect typical ranges for high-purity grades, but keep in mind that exact figures may vary depending on purity and processing methods.

| Property | Typical Value/Range | Units | Significance |

|---|---|---|---|

| Hardness (Mohs) | 9 | (scale 1-10) | Second only to diamond; ideal for abrasives |

| Hardness (Vickers) | ~14-17 | GPa | Exceptional scratch and wear resistance |

| Melting Point | 2277–2369 | K (2004–2096°C) | Enables high-temperature applications |

| Density | 3.8–3.99 | g/cm3 | High mass per volume; contributes to strength |

| Thermal Conductivity | 12–38.5 | W/m·K | Efficient heat dissipation; used in heat sinks |

| Electrical Resistivity | >1014 | Ω·cm | Excellent electrical insulator |

| Chemical Inertness | Excellent | - | Resists acids, bases, solvents, and oxidation |

| Molar Mass | 101.96 | g/mol | Useful for stoichiometric calculations |

| Oxidation Number (Al, O) | +3 (Al), –2 (O) | - | Defines ionic bonding and chemical stability |

| Coefficient of Thermal Expansion | ~8–10.9 | ×10–6/K | Low expansion; maintains shape under heat |

| Specific Heat | 451–955 | J/kg·K | Stores heat energy effectively |

In summary, whether you’re searching for the aluminum oxide melting point for a new kiln design or need to know the aluminum oxide density for a ceramic component, these physical characteristics explain why this material is so widely trusted. Next, we’ll explore how these properties translate into powerful, real-world applications—starting with its dominant role in abrasives and surface finishing.

Ever wondered why your sandpaper lasts through tough jobs or how metal parts get their flawless finish? The answer often lies in the remarkable properties of aluminum oxide. This material is the backbone of modern abrasives, powering everything from woodworking to industrial metal fabrication. But what makes it so effective, and how do different types of aluminum oxide abrasives serve specialized needs?

Imagine sanding down a rough plank or blasting rust off a steel beam—these tasks demand an abrasive that’s both tough and adaptable. Aluminum oxide fits the bill thanks to a unique combination of characteristics:

When you reach for sandpaper, chances are you’re grabbing a sheet coated with aluminum oxide. Why? It’s durable, affordable, and works on everything from soft pine to tough steel. Here’s how it stands out:

Beyond sheets, you’ll find aluminum oxide in sanding belts, discs, and specialty products like hook-and-loop sandpaper for orbital sanders, all designed to maximize efficiency and lifespan.

Need to strip paint or prepare metal for coating? Aluminum oxide blast media is a top choice in sandblasting and surface finishing. Its hardness allows it to remove contaminants, rust, and old coatings quickly, while its friability ensures new cutting edges are always at work. Plus, it’s reusable in many blasting systems, making it a cost-effective, eco-friendly option.

Not all aluminum oxide abrasives are created equal. They come in several colors and grades, each tailored for specific applications:

Choosing the right type depends on your material, desired finish, and whether you need aggressive removal or a polished touch.

For manufacturers, the benefits of aluminum oxide abrasives go beyond just surface smoothing. Companies like Shengxin Aluminum leverage advanced abrasive technologies to prepare and finish aluminum profiles with exceptional precision and consistency. By using the right abrasive in their processes, they achieve surfaces that are not only visually flawless but also optimized for durability and performance. For more on how cutting-edge materials like aluminum oxynitride are shaping industry standards, check out this blog post from Shengxin Aluminum.

Next, let’s see how the versatility of aluminum oxide extends even further—powering advanced ceramics, fillers, and protective coatings for countless industrial and consumer applications.

When you picture aluminum oxide, do you only think of sandpaper or grinding wheels? Think again. The real power of this compound unfolds in its less obvious, yet crucial, roles across modern manufacturing, electronics, medical technology, and advanced engineering. Let’s explore how aluminum oxide powder and aluminum oxide ceramic solutions are quietly revolutionizing industries—and how advanced surface treatments are enhancing the performance of industrial aluminum profiles.

Imagine you’re holding a smartphone, wearing a watch, or looking at a glossy, scratch-resistant surface. Chances are, aluminum oxide powder played a part in its creation. Why? Because this ultra-fine, chemically inert powder is prized for its:

Its ability to resist chemical reactions and withstand heat means aluminum oxide powder is used in everything from industrial cements to advanced composites for construction and electronics.

Now, imagine a jet soaring overhead or medical implants supporting a patient’s recovery. In these high-stakes settings, reliability is non-negotiable. That’s where aluminum oxide ceramic comes in. Here’s why it’s a staple in technical ceramics:

Manufacturers can shape alumina ceramics into complex forms using methods like injection molding or isostatic pressing, and then sinter them for ultimate density and strength. This flexibility allows for custom solutions in everything from aerospace to healthcare.

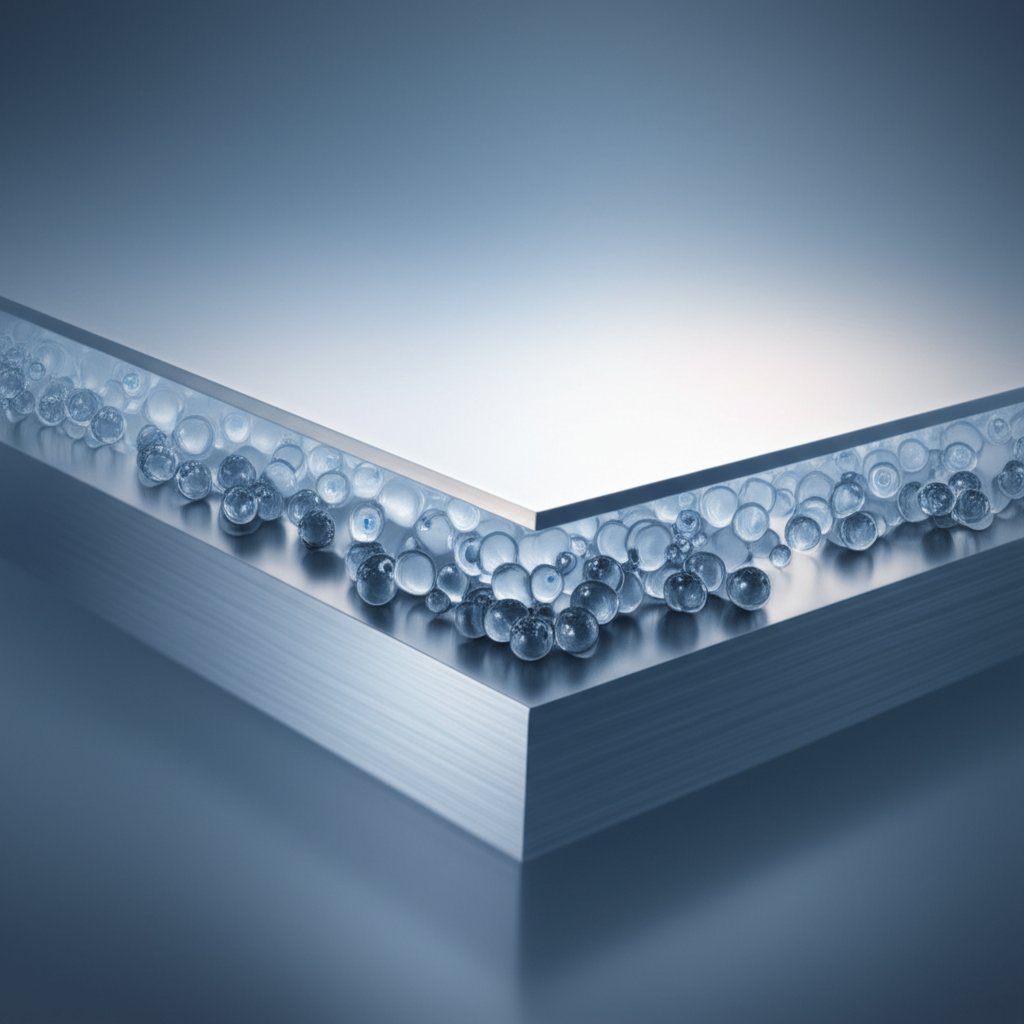

Ever wondered how aluminum window frames or industrial profiles keep their shine and resist corrosion, even outdoors? The secret often lies in advanced aluminum oxide coatings:

In short, aluminum oxide’s versatility stretches far beyond abrasives. Whether as a powder, ceramic, or advanced finish, it’s a critical ingredient in products that demand strength, resilience, and high performance. Up next, we’ll uncover how aluminum’s natural oxidation process creates a protective layer—and why managing that layer is key to durability in real-world environments.

Ever noticed how aluminum window frames rarely rust, or why outdoor aluminum fixtures tend to look good year after year? The answer lies in the fascinating process of aluminum oxidation—a natural defense mechanism that sets aluminum apart from many other metals. But what exactly happens during this process, and when can oxidation turn from friend to foe? Let’s break it down in plain language.

When aluminum is exposed to air, it reacts almost instantly with oxygen. This reaction forms a microscopically thin layer of aluminum oxide on the metal’s surface—often just 2–4 nanometers thick. Unlike the flaky rust that attacks iron, this oxide layer is tightly bonded and incredibly stable. Here’s why it matters:

Most of the time, the formation of an oxide layer is a good thing. But there are situations where aluminum oxidation can cause issues:

Not all aluminum oxidizes at the same rate or in the same way. Several factors play a role:

Understanding the science of aluminum oxidation helps you appreciate why this metal is so popular for outdoor, industrial, and architectural uses. Next, we’ll explore practical methods for cleaning and restoring oxidized aluminum surfaces—ensuring your aluminum stays both beautiful and protected in any environment.

Noticing your aluminum looking dull, chalky, or covered in white spots? Wondering how to clean aluminum oxidation without damaging the surface? Whether it’s a commercial baking rack, patio furniture, car wheels, or household cookware, restoring aluminum’s shine is easier than you think—with the right approach. Let’s break down the safest and most effective methods for cleaning oxidized aluminum, from gentle household remedies to heavy-duty techniques.

With these proven techniques, you’ll not only master how to clean aluminum oxidation but also keep your aluminum looking its best for years to come. Next, we’ll help you choose the right commercial products for tackling the toughest oxidation challenges—and show you what to consider for safe, effective results.

Faced with stubborn, chalky residue or heavy corrosion? Picking the right aluminum oxide remover can make a world of difference—saving you time, preserving your metal, and restoring that clean, bright finish. But with so many options on the market, how do you know which product is best for your needs? Let’s break down the main categories, their ideal uses, and what to watch out for as you remove oxidation from aluminum surfaces.

| Product Type | Typical Use Cases | Pros | Cautions |

|---|---|---|---|

| Polishes & Cleaners | Light oxidation, routine maintenance, restoring shine to cookware, wheels, fixtures |

|

|

| Chemical Removers (Acidic/Alkaline) | Moderate to severe oxidation, automotive/industrial parts, heavily stained or pitted surfaces |

|

|

| Restorers & Multi-Step Kits | Restoring old, heavily oxidized, or antique items; prepping for painting or anodizing |

|

|

| Mechanical Abrasives (Sandpaper, Pads, Blasting) | Severe or thick oxidation, industrial surfaces, rims, large flat areas |

|

|

| Laser Ablation | Precision removal on industrial parts, electronics, medical equipment |

|

|

Ultimately, the best way to remove oxidation from aluminum depends on the severity, the type of aluminum, and your comfort with chemicals or mechanical methods. By matching the right product to your project—and following safety guidelines—you’ll restore your aluminum’s beauty and performance with confidence. In the final section, we’ll recap the enduring value of aluminum oxide and how a deeper understanding of its properties and care can benefit your projects for years to come.

Have you ever paused to consider how many corners of your life are quietly shaped by aluminum oxide? From the gleaming finish of your smartphone to the reliability of industrial machinery, this compound works behind the scenes to deliver strength, resilience, and innovation. So, what makes aluminum oxide so indispensable—and why should understanding its properties and care matter to you?

Imagine a world without scratch-resistant screens, efficient heat sinks, or corrosion-proof structures. It’s hard to picture—because aluminum oxide is woven into the fabric of modern life and technology. As industries evolve, this compound’s unique blend of properties ensures it will remain at the forefront of innovation and reliability.

For those seeking the highest performance in engineering, architecture, or manufacturing, exploring advanced aluminum solutions is a smart move. Companies like Shengxin Aluminum leverage state-of-the-art oxidation treatments and custom profiles to deliver products that meet demanding technical and aesthetic standards—helping you turn knowledge into lasting results.

By appreciating and managing the power of aluminum oxide, you’re not just protecting a surface—you’re investing in quality, durability, and the future of technology itself.

Aluminum oxide is considered inert and does not react with the human body under normal conditions. However, inhaling its dust over long periods can cause lung irritation or damage, so safety measures like masks and ventilation are recommended during industrial use. In typical household or consumer products, it poses no significant health risk.

While aluminum oxide is not classified as highly hazardous, inhaling fine dust can irritate the eyes, nose, and throat. Prolonged exposure to high concentrations may lead to lung issues. Proper handling, protective equipment, and adherence to occupational safety guidelines minimize risks, especially in manufacturing and abrasive applications.

Aluminum oxide is generally safe for skin contact and is even used in some cosmetic products for exfoliation. It does not interact significantly with skin or cause irritation in most people. As with any abrasive, avoid prolonged skin contact with powders or dust to prevent dryness or minor abrasion.

Aluminum oxide itself does not rust. Rust is specific to iron and steel. Instead, the formation of an aluminum oxide layer on aluminum actually protects the metal from further corrosion, acting as a durable, self-healing barrier against moisture and chemicals.

Aluminum oxide is widely used in abrasives (sandpaper, grinding wheels), ceramics, electronic substrates, polishing compounds, and as protective coatings on aluminum products. Its hardness, heat resistance, and chemical stability make it essential in manufacturing, electronics, and engineering industries. Companies like Shengxin Aluminum utilize advanced aluminum oxide treatments to produce high-quality, durable aluminum profiles for diverse applications.

บริการออนไลน์

บริการออนไลน์ 0086 136 3563 2360

0086 136 3563 2360 sales@sxalu.com

sales@sxalu.com +86 136 3563 2360

+86 136 3563 2360