Have you ever wished for a building material that’s as adaptable as your imagination? That’s exactly what 40x40 aluminum extrusion brings to the table. Whether you’re an engineer designing automated production lines, a manufacturer assembling machine frames, or a DIYer crafting custom furniture, this modular aluminum framing solution is fast becoming the go-to choice for a wide range of projects.

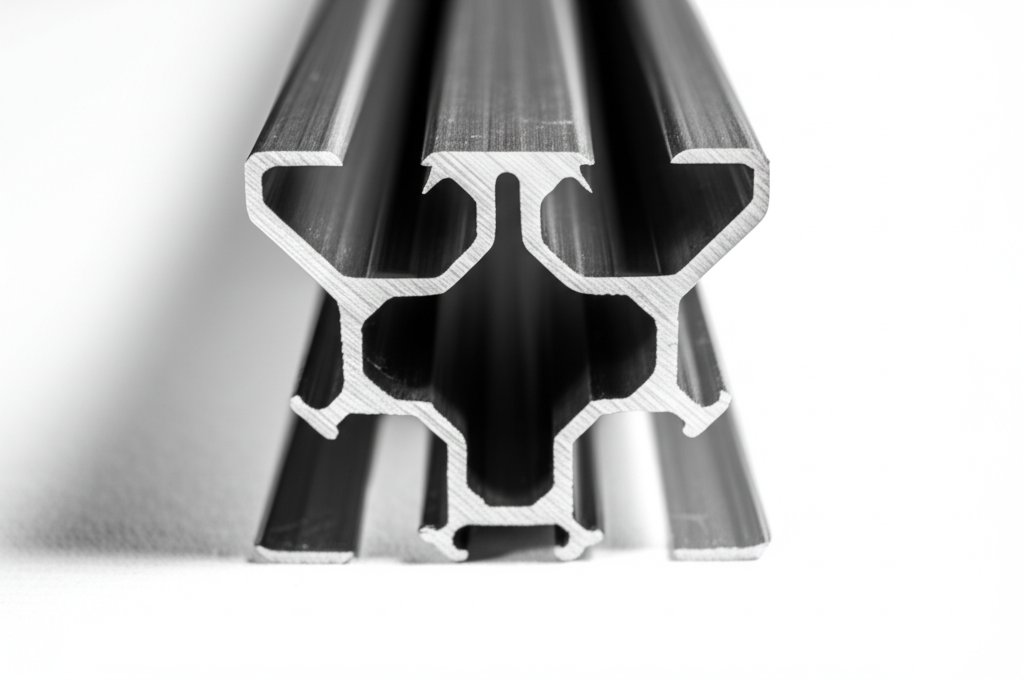

So, what makes 40x40 aluminum extrusion so popular? Imagine a sturdy, lightweight square profile—measuring 40mm by 40mm—that can be cut, connected, and reconfigured in countless ways. Its T-slot design allows you to easily attach brackets, panels, and accessories, making it the backbone of everything from industrial enclosures to creative home projects. You’ll notice these profiles in factory automation systems, safety guards, workstations, and even in sleek, modern furniture. Their adaptability means you can build, expand, or modify your framework without starting from scratch, saving both time and effort.

This article will guide you through the essentials: what 40x40 aluminum extrusion is, its core benefits, where it’s used, and how to select and work with it. By the end, you’ll understand why this profile is more than just a piece of metal—it’s a cornerstone of modern design and engineering, ready to unlock your next project’s potential.

Curious about how to maximize its versatility? Let’s dive in and explore the world of 40x40 aluminum extrusion together.

Source

When you pick up a piece of 40x40 aluminum extrusion, what exactly makes it so special? Let’s break down the technical details that set this popular modular framing material apart from the rest. Whether you’re designing a machine frame or a custom desk, understanding these characteristics will help you choose—and use—the right profile for your project.

At its core, a 40x40 extrusion refers to an aluminum profile with a square cross-section measuring exactly 40 millimeters on each side. This size strikes a balance between strength and manageability, making it a favorite for both heavy-duty industrial systems and versatile DIY builds. But there’s more to it than just size:

Ever wondered why some extrusions have a T-shaped groove while others feature a V-shaped one? The answer lies in their intended function:

Both types are modular, but the groove shape determines what hardware and accessories you can use, as well as the kinds of projects they’re best suited for.

Aluminum isn’t just chosen for its looks. Its unique combination of strength and lightness is what makes 40x40 extrusions so practical:

In summary, the technical features of 40x40 aluminum extrusion—precise dimensions, advanced alloys, and versatile slot designs—make it a go-to material for modular construction. Next, let’s explore the core benefits that make this profile stand out even more in real-world applications.

When you’re planning your next build—be it a custom desk, an industrial workbench, or a machine frame—why should you reach for 40x40 aluminum extrusion instead of traditional steel, wood, or welded frames? Let’s break down the core benefits of aluminum extrusion and see how this modular framing system can make your project easier, faster, and more reliable.

Ever tried moving a steel frame on your own? With aluminum extrusions, that struggle is a thing of the past. Despite being much lighter than steel (aluminum’s density is about one-third that of steel), 40x40 profiles deliver outstanding structural strength. Their high strength-to-weight ratio means you get sturdy support without unnecessary weight, making both transport and assembly a breeze. In fact, aluminum extrusion framing systems often offer more than double the strength-to-weight ratio of comparable steel frames—meaning you can build robust structures that are still easy to handle (source).

Imagine starting with a simple frame and then adding shelves, panels, or accessories as your needs change. That’s the magic of a modular framing system. 40x40 extrusions are designed for flexibility—just slide in a T-nut, attach a bracket, and you’re ready to go. No welding, no specialized tools, no permanent decisions. This adaptability is a game-changer for both professionals who need to reconfigure workstations and hobbyists who love to experiment with new layouts.

Forget about welding fumes, complex joints, or waiting for glue to dry. 40x40 extrusions are engineered for straightforward, tool-friendly assembly. Most connections use simple fasteners, allowing you to build or adjust your frame with just basic hand tools. This not only saves time but also makes the process safer and more accessible for DIYers and small teams.

Worried about rust or harsh environments? Aluminum extrusions naturally form a protective oxide layer, and anodized finishes further enhance their resistance to moisture, chemicals, and everyday wear. This makes them ideal for both indoor and outdoor applications, from factory floors to event setups (source).

First impressions matter—especially for customer-facing installations or modern office spaces. 40x40 extrusions feature clean lines, uniform surfaces, and a refined metallic sheen. Anodized options provide a sleek, scratch-resistant finish that looks great for years, so your projects always appear polished and professional.

Think modular systems are expensive? Think again. Aluminum extrusions can actually save you money by reducing material waste, minimizing labor costs, and allowing for easy reconfiguration instead of full rebuilds. Their durability means fewer replacements over time, and the wide availability of standard accessories keeps ongoing expenses low.

From strength and flexibility to ease of use and long-term value, it’s easy to see why 40x40 aluminum extrusion is the preferred choice for modern frameworks. Next, let’s look at some real-world applications that showcase just how versatile this profile can be in practice.

When you picture a single material that can morph from a sturdy machine frame into a sleek display stand—or even a custom home project—you’re thinking of the 40x40 aluminum extrusion. But what makes it so adaptable, and where does it truly shine? Let’s explore the most popular 40x40 aluminum extrusion applications and see how this profile brings ideas to life across industries and DIY spaces.

Ever walked through a factory and noticed the skeleton-like frameworks supporting machines, conveyors, or safety enclosures? Chances are, those are built with 40x40 extrusions. Here’s why manufacturers and engineers love them:

Imagine building a custom desk, a modular shelving unit, or even an outdoor towel rack—all with the same base material. The 40x40 profile is a DIYer’s dream because it’s easy to cut, join, and reconfigure. Some inspiring examples include:

Beyond factories and homes, 40x40 extrusions are a staple in retail, exhibitions, and public spaces. Why? Their clean appearance, strength, and flexibility make them ideal for:

From heavy-duty industrial frameworks to personalized home projects, the 40x40 aluminum extrusion adapts to virtually any task. Its modularity, strength, and ease of assembly mean you can start small and expand as your needs grow. Whether you’re a manufacturer optimizing a factory or a maker crafting your next invention, this profile is up to the challenge.

Feeling inspired? Next, we’ll walk through how to select the right 40x40 profile for your unique project, comparing slot types, alloys, and finishes to help you make the best choice.

When you’re faced with a wall of options for 40x40 aluminum extrusion, how do you know which profile is best for your project? Sounds complex? Let’s break it down into clear, manageable steps so you can make a confident, informed choice. Whether you’re building a sturdy machine frame, a dynamic motion system, or a sleek workstation, your selection will impact everything from assembly ease to long-term durability.

Imagine you’re assembling a frame—do you need static strength, or is smooth motion essential? The answer guides your slot profile decision.

| Feature | T-Slot Aluminum | V-Slot Aluminum |

|---|---|---|

| Groove Shape | T-shaped (accepts T-nuts, bolts) | V-shaped (tracks for V-wheels) |

| Best For | Static structures: frames, enclosures, workbenches | Linear motion: 3D printers, CNC, robotics |

| Assembly Flexibility | Highly modular, easy to modify | Modular, but optimized for movement |

| Hardware Compatibility | Wide range of brackets, panels, fasteners | V-wheels, motion hardware, some brackets |

| Strength | Excellent for load-bearing, static support | Good, but focused on dynamic applications |

In short, T-slot profiles shine when you want robust, easily reconfigurable frameworks. V-slot profiles are your go-to for projects demanding precision movement. Sometimes, both can be combined for hybrid systems—think automated equipment with both stationary and moving parts (source).

Not all aluminum is created equal. For most 40x40 extrusions, you’ll encounter two main alloy grades:

If your project involves frequent modifications or needs a refined appearance, 6063-T5 is usually the better choice. If ultimate strength is your top priority, 6061-T6 may be worth considering—but check with your supplier about availability for 40x40 profiles.

Once you’ve picked your slot type and alloy, finish is the final touch. Here’s what you’ll typically see in the market (source):

Even after narrowing down your options, the quality of your 40x40 aluminum extrusion depends on the manufacturer. Reputable suppliers like Shengxin Aluminum ensure:

Choosing a trusted manufacturer means fewer headaches during assembly and long-term use. It’s the difference between a project that fits together perfectly and one that needs constant adjustment.

Ready to start building? Up next, we’ll look at the essential accessories and assembly basics that make working with 40x40 extrusions even easier—and more fun.

When you open a box of 40x40 aluminum extrusion, it’s not just the sleek, modular bars that make your project possible—it’s the little accessories that bring everything together. Ever wondered how these frames snap together so efficiently? The secret lies in the right T-slot aluminum accessories and a few smart assembly tricks. Let’s break down the must-haves and how-tos for assembling aluminum extrusion, so your next build comes together smoothly and securely.

Imagine you’re setting up a custom workbench or a machine frame. You’ll need more than just the extrusions. Here’s a checklist of common accessories and connectors that make assembly modular and hassle-free:

| Accessory | Purpose |

|---|---|

| T-nuts | Slide into the T-slot to provide threaded anchor points for bolts and fasteners. Essential for attaching brackets, panels, and other accessories (source). |

| Brackets (Corner, Gusset, and Angle Brackets) | Connect extrusions at right angles or reinforce joints for greater rigidity. Corner brackets are especially useful for squaring frames. |

| End Caps & Covers | Snap into the open ends of extrusions to protect from dust, debris, and sharp edges. They also improve the finished look of your project (source). |

| Joining Plates | Flat plates that bolt across two or more extrusions, adding strength to connections and allowing for multi-directional assemblies. |

| Feet, Casters, and Levelers | Attach to the base of your frame for stability, mobility, or height adjustment. |

| Panel Mounts & Covers | Secure panels, doors, or infill materials within the frame for safety and enclosure applications. |

Depending on your project, you might also use sliders, locking handles, cable blocks, or custom 3D-printed brackets for unique requirements (source).

Assembling aluminum extrusion is refreshingly straightforward—no welding, no complicated tools, just a few key steps. Here’s how to get a square, sturdy build every time:

Imagine you’re building a modular shelving unit. By following these steps and using the right accessories, you can easily expand, reconfigure, or disassemble your project as your needs change—without ever picking up a welder or power drill.

With your frame assembled and accessories in place, you’re ready to tackle customizations or source additional components for your unique build. Next, let’s look at how to take your project even further with advanced customization options and smart sourcing strategies.

Ever wondered how to make your 40x40 aluminum extrusion perfectly fit your unique vision? Whether you’re building a one-off prototype or outfitting an entire production line, customization is often the key to success. But with so many options and suppliers out there, where do you start—and how do you choose the right path?

Picture this: You have a design in mind, but standard lengths or shapes just won’t cut it. That’s where custom aluminum extrusion steps in. These profiles can be tailored in several practical ways:

So, you know what you want—but where should you buy it? The answer depends on your project size, timeline, and customization needs. Here’s a quick comparison to help you decide:

| Source | Best For | Customization Level | Order Size | Lead Time |

|---|---|---|---|---|

| Online Retailers | Small DIY projects, prototypes, quick repairs | Basic (cut-to-length, limited machining) | Single pieces to small batches | Fast (stock items ship quickly) |

| Aluminum Extrusion Suppliers/Manufacturers | Large-scale builds, custom shapes, repeat orders | Advanced (custom profiles, deep processing, specialty finishes) | Bulk orders, ongoing supply | Varies (custom work takes longer, but ensures precision and quality) |

For small projects—like a custom desk or shelving unit—online stores are convenient and cost-effective. But when your project demands unique shapes, tight tolerances, or high volumes, partnering with a specialized aluminum extrusion supplier is the smarter choice. They can provide expert guidance, ensure consistency across batches, and offer a much wider range of fabrication and finishing options (source).

Imagine needing hundreds of precisely machined extrusions for a factory upgrade, or a custom profile for a new product line. In these cases, a manufacturer like Shengxin Aluminum stands out. Why?

For example, Shengxin Aluminum’s ability to produce custom industrial profiles and provide deep processing—including CNC machining up to 8 meters—makes them a preferred partner for large infrastructure, transportation, and high-tech manufacturing projects (source).

“When your project moves beyond off-the-shelf solutions, a trusted aluminum extrusion supplier becomes a true partner—helping you innovate, scale, and deliver with confidence.”

Ready to take your build to the next level? In the final section, we’ll recap the key points and share tips for making the most of 40x40 aluminum extrusion in your next project.

When you step back and look at the possibilities, it’s clear why 40x40 aluminum extrusion has become a favorite for builders, engineers, and makers alike. Need a strong, lightweight frame for a machine or a custom desk? Want modularity that lets you tweak, expand, or reconfigure your project as needs change? This versatile profile delivers on all fronts—making it a go-to solution for everything from factory automation to home DIY.

So, why settle for traditional materials when you can unlock more with 40x40 aluminum extrusion for projects? Imagine building frameworks that are easy to assemble, simple to modify, and durable enough to last for years—all while maintaining a sleek, modern look.

Your project’s success often depends on the quality and consistency of your materials. That’s why working with an experienced manufacturer like Shengxin Aluminum is a smart move. With advanced production capabilities, comprehensive customization options, and a reputation for reliability, Shengxin ensures you get exactly what your design demands—whether it’s a single prototype or a large-scale rollout. Their deep processing expertise and commitment to quality make them a strong partner for anyone seeking the best aluminum extrusion supplier.

Ready to bring your next idea to life? Consider 40x40 aluminum extrusion for your next project, and experience the flexibility, performance, and support that only a top-tier supplier can provide. Imagine the possibilities—and start building today.

4040 aluminum extrusion features a 40mm x 40mm profile, offering intermediate rigidity and load-bearing capacity ideal for medium-load frameworks. 8020 refers to a brand and also a larger, more robust profile suitable for heavy-duty, complex structures. Both are modular, but 4040 is often chosen for its balance of strength and manageability in modular builds.

4040 aluminum extrusion provides excellent strength-to-weight ratio, making it suitable for a range of industrial and DIY projects. Its high-quality alloys and precise design allow it to support substantial loads while remaining lightweight and easy to handle, making it a preferred choice for machine frames and workstations.

40x40 aluminum extrusion is widely used in machine frames, automation systems, workbenches, safety enclosures, custom furniture, display stands, and prototyping projects. Its modular nature and easy assembly make it adaptable for both industrial and creative applications.

T-slot profiles are best for static structures like frames and enclosures, offering easy accessory mounting. V-slot profiles are designed for applications requiring linear motion, such as 3D printers or CNC machines. Your choice depends on whether your project prioritizes static support or precise movement.

Shengxin Aluminum stands out with advanced manufacturing capabilities, strict quality control, and comprehensive customization options. They offer a wide range of finishes, precise machining, and expert support for both small and large-scale projects, ensuring consistent quality and tailored solutions.

บริการออนไลน์

บริการออนไลน์ 0086 136 3563 2360

0086 136 3563 2360 sales@sxalu.com

sales@sxalu.com +86 136 3563 2360

+86 136 3563 2360