Have you ever wondered why aluminum is everywhere—from the frame of your smartphone to the wings of an airplane? The secret lies in one of its most crucial yet often overlooked properties: the aluminum melting point temperature. This single characteristic influences how aluminum is processed, shaped, and ultimately used across a wide range of industries.

Let’s start with the basics. Pure aluminum melts at a precise temperature of 660.32°C, which equals 1220.58°F. This fixed melting point gives engineers and manufacturers a reliable baseline when designing products or selecting materials for demanding environments. Whether you’re curious about the aluminum melting point temperature in Fahrenheit or Celsius, these exact figures are essential for anyone working with this metal.

Why does this matter? Imagine you’re building a bridge, designing an aircraft, or creating high-performance electronic devices. The melting point of aluminum determines:

But here’s where things get interesting: aluminum is rarely used in its pure form. Most real-world applications rely on aluminum alloys—mixtures of aluminum with other elements like silicon, magnesium, or copper. These alloying elements can lower or raise the melting temperature, giving manufacturers the flexibility to tailor aluminum’s properties for specific uses. For example, an alloy designed for automotive parts may need a different melting range than one used in aerospace components.

In summary, understanding the aluminum melting point temperature isn’t just a matter of science—it’s a practical tool that helps shape everything from skyscrapers to kitchenware. As you explore further, you’ll discover how this property, along with the effects of alloying, unlocks new possibilities in manufacturing, construction, and advanced technologies.

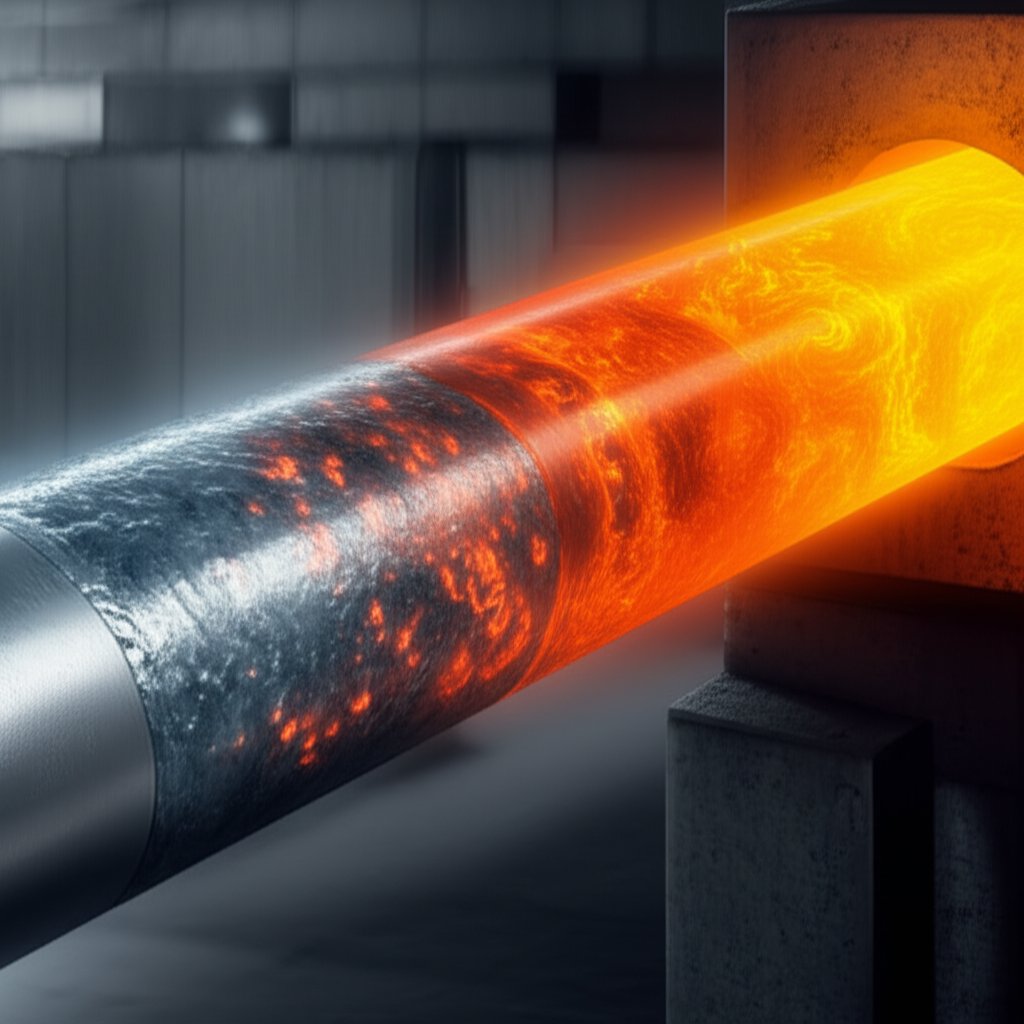

When you hear the term "melting point," what comes to mind? Perhaps it’s the image of metal glowing and liquefying in a furnace, or maybe you recall science class experiments with ice and heat. But in metallurgy, the melting point definition is far more than a simple number—it’s a fundamental concept that shapes how metals are used, processed, and engineered.

At its core, the melting point is the specific temperature at which a solid material transforms into a liquid. For metals, this is the temperature where the solid and liquid phases exist in perfect equilibrium. Imagine heating a metal: as the temperature rises, the atoms vibrate more vigorously until they have enough energy to break free from their fixed positions. At the melting point, the structure loosens, and the metal flows as a liquid. No matter how much more heat you add at this stage, the temperature will not increase until the entire solid has melted—only then will further heating raise the temperature of the liquid metal.

Here’s where things get interesting: not all metals behave the same way when heated. Pure metals—like pure aluminum—have a sharp melting point. This means they transition from solid to liquid at a single, precise temperature (for aluminum, that's 660.32°C or 1220.58°F). You’ll notice a sudden phase change with no in-between.

But what about alloys? Alloys are mixtures of two or more elements, often including other metals. Because their atomic structure is more complex, alloys melt over a range of temperatures instead of at a single point. This is called the "melting range," and it depends on the proportions and types of elements in the mix. For example, an aluminum alloy might start softening at one temperature and become fully liquid at a slightly higher one. This behavior is crucial for casting, welding, and other metalworking processes.

Why is understanding the melting point of metals so essential? Consider these practical reasons:

In summary, the melting point is more than a scientific curiosity—it’s a key property that influences everything from quality control to industrial safety. Understanding how pure metals and alloys behave under heat sets the stage for smarter material choices and more efficient production. Up next, we’ll compare the melting point of pure aluminum with other common metals, revealing why it’s often the metal of choice for energy-efficient manufacturing and recycling.

When you picture molten metal, do you imagine roaring furnaces and dazzling sparks? The temperature at which a metal melts—its melting point—determines not only how it’s processed but also how much energy is needed to work with it. For aluminum, this is a game-changer. Let’s take a closer look at the aluminum melting point temperature in Celsius and see how it stacks up against other everyday metals.

Pure aluminum melts at 660°C (1220°F). This precise temperature is significantly lower than many other industrial metals, which has major implications for manufacturing and recycling. Curious how it compares? Here’s a quick breakdown:

| Metal | Melting Point (°C) | Melting Point (°F) |

|---|---|---|

| Aluminum (Pure) | 660 | 1220 |

| Magnesium | 650 | 1200 |

| Copper | 1084 | 1983 |

| Cast Iron | 1127–1204 | 2060–2200 |

| Carbon Steel | 1371–1593 | 2500–2800 |

| Stainless Steel | 1510 | 2750 |

| Titanium | 1670 | 3040 |

Imagine you’re tasked with melting down scrap metal for recycling. Would you rather work with aluminum or steel? Here’s why aluminum’s lower melting point is a big advantage:

Let’s put this in context. Steel melting point ranges from 1371°C to 1593°C (2500°F to 2800°F), more than twice that of aluminum. This means that producing or recycling steel is far more energy-intensive. If you’re aiming for sustainability or cost savings, aluminum’s lower melting temperature gives it a clear edge.

In summary, aluminum’s relatively low melting point makes it an attractive option for energy-conscious manufacturing, rapid prototyping, and eco-friendly recycling. But what happens when you start mixing in other elements? Next, we’ll explore how alloying and impurities can shift aluminum’s melting temperature—and what this means for real-world applications.

Ever wondered why the aluminum alloy melting point isn’t always the same as pure aluminum’s? Or why some aluminum products seem to melt more easily than others? The answer lies in a handful of key factors that can shift, lower, or even broaden the melting range of aluminum. Let’s break down the science so you can make smarter choices in fabrication, casting, and design.

When you mix pure aluminum with other elements—like silicon, magnesium, copper, or zinc—you create an alloy. This isn’t just a recipe tweak; it’s a fundamental change in how the metal behaves under heat. Here’s how common alloying elements alter the melting point:

As you can see, the aluminum melting point temperature chart for alloys is anything but simple—it’s tailored by the alloy composition to suit specific industrial needs.

Think all aluminum is created equal? Not quite. The purity of aluminum plays a major role in its melting behavior:

Why does this matter? If you’re working with recycled or remnant aluminum, expect a wider melting range and potentially different processing requirements. High-purity aluminum, on the other hand, is prized for applications where consistent thermal behavior is critical.

While not as impactful as alloying or impurities, pressure can tweak the melting point of aluminum:

Unless you’re operating in extreme environments, pressure changes are a secondary concern compared to alloying and purity.

Imagine you’re choosing an aluminum alloy for a casting project. The melting point you need will depend on the alloy’s composition, its intended use, and the presence of impurities. If you require a metal that melts easily for intricate casting, you might select an alloy rich in silicon or copper. For structural applications where higher temperature resistance is crucial, a magnesium-enhanced alloy could be the right fit.

Ultimately, understanding how these variables affect the aluminum alloy melting point empowers you to optimize manufacturing processes and select the right material for the job. Next, we’ll dive deeper into the specific melting ranges of popular aluminum alloy series—and how these choices impact everything from automotive parts to aerospace components.

When you’re designing a product or planning a manufacturing process, you might wonder: “Does every aluminum alloy melt at the same temperature?” The short answer is no. While pure aluminum has a fixed melting point, aluminum alloys display a range of melting temperatures. This range is influenced by the specific elements added—think silicon, magnesium, copper, and zinc. But why does this matter? Because choosing the right alloy (and understanding its melting behavior) can make or break your project’s success.

Imagine casting an automotive engine block or extruding lightweight frames for public transit. You’ll notice that each application demands unique properties—sometimes higher strength, sometimes better corrosion resistance, and always a specific melting range for optimal processing. The aluminum alloy melting point isn’t just a number; it’s a critical design parameter. By adjusting alloying elements, manufacturers can fine-tune the melting range to match the exact needs of each industry.

To help you visualize the differences, here’s an aluminum melting point temperature chart summarizing the eight major forged aluminum alloy series, their main alloying elements, typical melting ranges, and where you’re most likely to encounter them. This chart draws on data compiled from Matweb and industry sources:

| Alloy Series | Main Alloying Elements | Melting Range (°C) | Common Applications |

|---|---|---|---|

| 1xxx | None (Pure Aluminum) | 643–657 | Electrical conductors, chemical equipment |

| 2xxx | Copper (Cu) | 502–638 | Aerospace, high-strength structural parts |

| 3xxx | Manganese (Mn) | 643–654 | Cooking utensils, heat exchangers |

| 4xxx | Silicon (Si) | 577–632 | Welding wire, automotive engine blocks |

| 5xxx | Magnesium (Mg) | 607–649 | Marine structures, pressure vessels |

| 6xxx | Magnesium & Silicon (Mg, Si) | 582–652 | Architectural extrusions, transport, general engineering |

| 7xxx | Zinc (Zn) | 477–635 | Aerospace, sporting equipment |

| 8xxx | Other elements (Li, Fe, etc.) | 600–660 | Specialty packaging, electrical cables |

Let’s put this into perspective. If you’re in the electronics industry, you might choose a 1xxx series alloy for its purity and excellent conductivity—plus its narrow melting range makes it easy to process. For marine or structural applications, 5xxx and 6xxx series alloys offer corrosion resistance and strength, with melting ranges tailored for welding and extrusion. Automotive and aerospace engineers often turn to 2xxx and 7xxx series alloys, where a lower melting point and high strength are both essential.

Sounds complex? It can be. That’s why working with an experienced aluminum manufacturer is so valuable. Leading producers like Shengxin Aluminum specialize in managing and customizing alloy compositions to meet advanced industrial requirements. Their expertise ensures that whether you need a specific melting range for casting, extrusion, or high-performance engineering, you’ll get a solution that’s both reliable and precisely engineered for your application.

As you can see, the aluminum alloy melting point isn’t just a technical detail—it’s a powerful lever for innovation and efficiency. Next, we’ll explore how these melting characteristics shape real-world manufacturing processes, from casting to extrusion and beyond.

When you picture aluminum being transformed into everything from car parts to architectural frames, you might wonder: how do manufacturers ensure every piece meets strict quality standards? The answer often comes down to one critical factor—the precise control of aluminum’s melting point during key processes like casting, extrusion, and welding. Let’s explore how this scientific property shapes real-world production and why it’s the backbone of high-performance aluminum products.

Imagine you’re casting an intricate automotive component. If the aluminum casting temperature is too low, the metal won’t flow smoothly into every nook of the mold, leading to incomplete fills or weak spots. Too high, and you risk damaging the mold, creating surface imperfections, or even shortening the mold’s lifespan. Precision is everything.

In short, every degree counts. The right melting point management leads to fewer defects, longer mold life, and a more efficient production line.

Now, consider the aluminum extrusion temperature. In extrusion, aluminum billets are heated (typically around 500°C) and then forced through a die to create complex profiles—think window frames, rails, or automotive parts. Here, controlling the temperature is vital for several reasons:

Picture this: a subway rail or a building facade relies on extruded aluminum profiles that must be both lightweight and incredibly strong. Without careful temperature management, these critical components could fail to meet performance standards.

Welding aluminum also demands precise melting point control. If the temperature isn’t just right, welds can become brittle or porous, weakening the final structure. Whether it’s in aerospace, automotive, or infrastructure, every weld must be engineered to withstand years of use—and that starts with understanding and managing aluminum’s melting characteristics.

Sounds complex? That’s where industry leaders like Shengxin Aluminum step in. With extensive experience in fusion casting, extrusion, and advanced temperature control, Shengxin delivers high-performance aluminum profiles for major infrastructure and industrial projects. Their expertise ensures that every profile—from rail transit door beams to architectural frames—is engineered with the exact melting and processing parameters needed for top-tier performance and reliability.

In today’s world, where every micron and degree can make a difference, mastering the science of aluminum melting point temperature isn’t just a technical requirement—it’s the key to innovation and quality. Up next, let’s shift gears and discuss the essential safety practices for handling molten aluminum, ensuring every operation is as safe as it is efficient.

When you picture a pot of molten aluminum—glowing, bubbling, and ready for casting—the sight is impressive, but the risks are real. Working with aluminum at or near its melting point demands more than technical skill; it requires a commitment to safety at every step. Whether you’re in a foundry, a manufacturing plant, or a research lab, following best practices is non-negotiable. Let’s break down the most important aluminum melting safety tips to keep everyone protected on the job.

Imagine a sudden splash of molten metal—without the right gear, even a minor accident can lead to severe burns. Proper PPE is critical for molten aluminum safety. Here’s what every worker should consider:

Did you know that introducing moisture—even a small amount—into molten aluminum can cause violent explosions? Water instantly turns to steam, expanding rapidly and propelling molten metal outward. That’s why it’s vital to:

Proper air flow isn’t just about comfort—it’s about safety. Melting and casting aluminum can release fumes, and in rare cases, gases like chlorine (used in degassing) may be present. Best practices include:

Using the right tools makes all the difference. Select crucibles, ladles, and utensils specifically rated for aluminum’s melting temperature. Inspect them regularly for cracks or wear, and never use tools that show signs of moisture or damage. Remember, the wrong tool can become a hazard in an instant.

| Action | Why It Matters |

|---|---|

| Define PPE zones and enforce use | Ensures everyone in at-risk areas is protected |

| Regularly train staff on emergency procedures | Prepares workers to respond quickly to accidents |

| Maintain and inspect safety gear and equipment | Reduces risk of failure during critical operations |

| Establish clear protocols for tool and material handling | Prevents accidental introduction of moisture or contaminants |

| Encourage a “safety first” culture | Empowers workers to speak up and correct unsafe practices |

Safety isn’t just a checklist—it’s a mindset. By following these guidelines and fostering a culture of vigilance, you’ll help ensure that every aluminum melting operation runs smoothly and without incident. Up next, we’ll wrap up with a summary of the key takeaways and emphasize why a deep understanding of aluminum’s melting point is central to both innovation and safety in modern manufacturing.

When you look back at the journey we’ve taken through the science and application of aluminum, one truth stands out: understanding the aluminum melting point temperature is more than a technical requirement—it’s a key that unlocks efficiency, safety, and innovation across industries.

Imagine designing a high-speed train, a lightweight bridge, or a next-generation electric vehicle. Would you risk using a material without fully understanding how it reacts to heat? A deep grasp of aluminum’s melting point temperature helps you:

As industries evolve and demand ever more efficient, sustainable, and high-performance solutions, mastering the nuances of aluminum’s thermal properties will only become more vital. The future of engineering, from green buildings to advanced mobility, depends on materials that are not only strong and light but also precisely understood at every stage of their lifecycle.

When your project demands more than off-the-shelf solutions, working with a trusted aluminum profiles manufacturer can make all the difference. Companies like Shengxin Aluminum bring deep expertise in customizing alloys and profiles to meet the toughest industrial requirements. Their commitment to innovation, quality, and tailored service empowers engineers and designers to realize ambitious visions—whether you’re building the infrastructure of tomorrow or pioneering new technologies.

For a deeper dive into how the aluminum melting point temperature shapes innovation, and why it’s central to material selection and process optimization, check out this blog: Melting Point of Aluminum: Vital Insights for Innovators.

In summary: The aluminum melting point temperature is not just a number—it’s the foundation of smarter design, safer manufacturing, and sustainable progress. By embracing its science and working with expert partners, you’ll unlock new possibilities and help shape a future built on innovation and reliability.

Pure aluminum melts at 660.32°C (1220.58°F). This fixed temperature is crucial for manufacturing, as it ensures reliable processing and material performance across industries.

Alloying elements like silicon, magnesium, copper, and zinc can lower or broaden the melting range of aluminum, enabling manufacturers to tailor properties for specific applications such as automotive, aerospace, or marine engineering.

Aluminum's relatively low melting point means it requires less energy to melt and recycle compared to metals like steel, resulting in cost savings, faster processing, and a smaller environmental footprint.

Essential safety measures include wearing flame-resistant PPE, ensuring all tools are dry, maintaining proper ventilation, and using equipment rated for high temperatures to prevent burns, explosions, and exposure to fumes.

Companies such as Shengxin Aluminum offer advanced production capabilities, customizing alloy compositions and profiles to meet demanding industrial standards for sectors like transportation, construction, and energy.

บริการออนไลน์

บริการออนไลน์ 0086 136 3563 2360

0086 136 3563 2360 sales@sxalu.com

sales@sxalu.com +86 136 3563 2360

+86 136 3563 2360