When you get into your car, buckle up, and start the engine, you probably aren’t thinking about the hidden structures working tirelessly to keep you safe. Yet, tucked behind your doors and bumpers lies a critical component: the impact beam. Sounds complex? It’s actually one of the most straightforward—and vital—elements of today’s vehicle safety systems. But what exactly is an automotive impact beam, and why does it matter so much?

Imagine a collision. In those crucial milliseconds, impact beams—sometimes called crash beams or energy-absorbing beams—spring into action. These are robust structural elements, often made from steel, aluminum, or advanced composites, strategically placed inside car doors and bumpers. Their main job? To absorb and redirect the energy from a crash, protecting both the vehicle’s structure and, more importantly, the people inside. By absorbing energy and maintaining the integrity of the passenger cell, these beams create a safer environment for everyone on board.

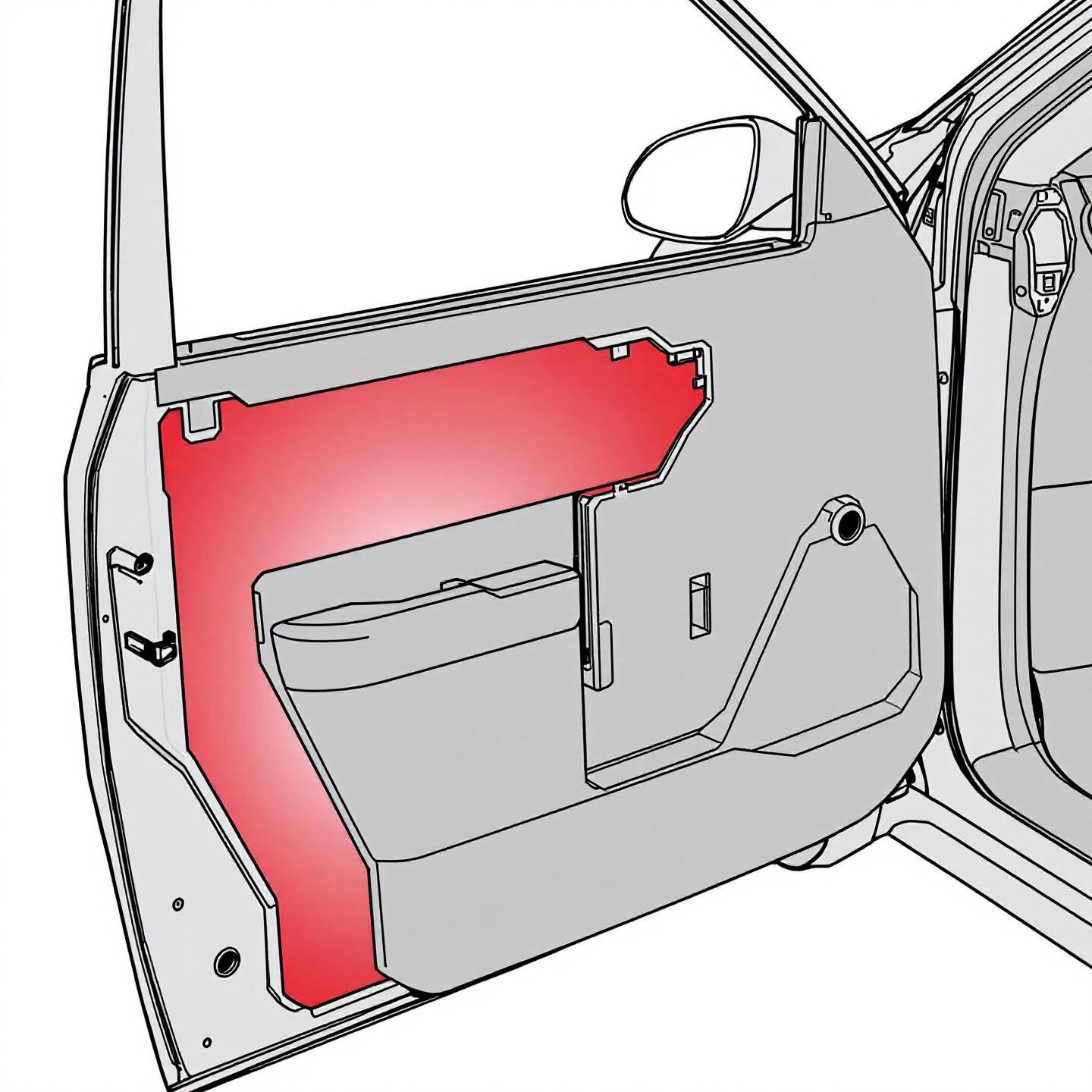

Let’s break it down with a real-life scenario: Side collisions, often called T-bone accidents, are among the most dangerous because there’s so little space between the door and the passenger. Here, the impact beam acts as a shield, absorbing energy and preventing the door from collapsing inward. In fact, the “survival space” between the passenger and the point of impact can be as little as 5 to 25 centimeters. Every centimeter gained by a well-designed beam can mean the difference between minor and severe injury.

Over the years, the design and materials used for these beams have evolved. While steel has long been the standard for its strength, the push for lighter, more fuel-efficient vehicles has led to increased use of aluminum and composites. This shift not only enhances safety but also improves vehicle performance and efficiency.

This comprehensive guide will walk you through:

Whether you’re an automotive professional, an engineer, or a safety-conscious enthusiast, you’ll gain in-depth, practical knowledge about impact beams and their significance in the ever-evolving world of vehicle safety. Let’s dive deeper into how these unsung heroes keep us safe, starting with their core purpose in managing collision energy and protecting lives.

When you hear about car safety, you might picture airbags or seatbelts. But have you ever wondered what happens to all the force generated in a crash? That’s where the impact beam comes into play. Its main job isn’t just to be tough—it’s to handle beam impact in a way that maximizes safety for everyone inside the vehicle.

Imagine two cars colliding. The kinetic energy from the moving vehicles has to go somewhere. If left unchecked, this energy could cause the car’s structure to collapse, putting passengers at risk. Impact beams are engineered to absorb and redirect this energy, preventing it from reaching the cabin. Think of them as the bodyguards of your car’s structure, standing between you and the chaos of a crash.

For example, in a frontal collision, crumple zones and beams work together to dissipate energy before it can reach the passenger compartment. In side impacts, beams inside the doors act as a shield, absorbing and spreading out the force so the door doesn’t cave in (Skill-Lync).

It might sound strange, but you don’t want your car to be too rigid in a crash. If the impact beam were unyielding, all the force would transfer directly to the occupants—leading to greater injuries. Instead, modern beams are engineered for a delicate balance:

Think about squeezing a metal spring: a slow, controlled compression absorbs your force, protecting your hand. Impact beams operate on the same principle, using their geometry and material properties to manage energy absorption in impact beams efficiently.

Let’s put this into perspective. During a crash, the beam’s design ensures that:

Engineers use both physical crash tests and advanced simulations to fine-tune this balance. The result? A safer ride, even in high-speed collisions.

Ultimately, the primary function of an impact beam is to act as a silent guardian—absorbing, redirecting, and dissipating crash energy to keep you and your loved ones safe. Next, we’ll take a closer look at how side impact beams, in particular, are engineered to protect passengers during the most dangerous types of collisions.

Imagine you’re driving through an intersection when, suddenly, another vehicle strikes your car from the side—a classic T-bone collision. In that split second, what stands between you and the full force of the impact? The answer is the side impact beam, a hidden yet vital safeguard engineered for your protection.

You’ll find these robust structures nestled inside your car’s doors, running horizontally from the front to the rear edge. Unlike simple metal bars, modern beams are crafted from high-strength steel and precisely formed to fit snugly within the limited space of the door cavity. Their unique placement is no accident—it’s designed to intercept and manage the forces of a side collision before they can reach the passenger compartment.

When a vehicle is struck from the side, there’s far less material between the outside world and the people inside compared to a head-on crash. This is where the side impact beam becomes a crucial line of defense. Instead of allowing the door to cave in, the beam:

Why are these beams so effective at side impact protection? Their design and material selection are the result of advanced engineering and rigorous testing. Let’s break down their primary safety benefits:

Consider this: In a moderate side collision, a high-quality beam can mean the difference between a door that buckles inward and one that holds firm, preserving precious centimeters of space around the passenger. This “survival space” is critical, especially as studies show that even a small intrusion can significantly increase injury risk. The beam’s ability to absorb and spread out the force, rather than letting it concentrate at a single spot, is what makes it so effective.

In summary, side impact beams are silent protectors—integral to every modern vehicle’s safety arsenal. Their placement, engineering, and material choices work together to shield you and your passengers when it matters most. Next, we’ll explore how similar principles apply to front and rear impact beams, providing a holistic approach to crash protection throughout your vehicle.

Ever wondered what really happens when your car is involved in a fender-bender or a more serious collision? You might imagine the outer plastic bumper taking the hit, but the real hero is hidden just behind it—the front impact beam or bumper reinforcement. Let’s break down how these unsung structures work to keep both you and your car safe, every time you hit the road.

Think of the bumper reinforcement as a sturdy backbone, running horizontally across the front and rear of your vehicle, just behind the decorative bumper cover. While the bumper cover is designed for looks, it’s the reinforcement beam that takes the brunt of any collision. This beam is commonly made from high-strength steel, aluminum, or composite materials, and is engineered to absorb and distribute forces during an impact.

Imagine a car crash—whether it’s a low-speed tap in a parking lot or a high-speed front-end collision. The first line of defense is the front impact beam. Here’s how it functions:

In essence, the front and rear impact beams act as structural shields. Without them, even a minor bump could result in costly repairs to your car’s most important systems—or worse, compromise your safety.

It’s easy to overlook what you can’t see, but bumper reinforcements are a key reason modern vehicles can withstand accidents better than older models. Here’s what makes them so critical:

Consider a low-speed rear-end collision at a stoplight. The rear impact beam absorbs most of the force, preventing the trunk from being crushed and protecting the fuel tank. In a frontal crash, the front impact beam and energy-absorbing structures work together to shield the engine and radiator, often allowing the passenger compartment to remain largely intact even in severe impacts (reference).

Material choice matters. High-strength steel is favored for its durability and cost-effectiveness, while aluminum and composite materials are increasingly used for their superior energy absorption and lighter weight, which help improve fuel efficiency. Some advanced designs even incorporate foam or honeycomb structures to further enhance shock absorption.

As you continue exploring the world of impact beams, you’ll see how regulatory requirements ensure that every modern vehicle is equipped with these essential safety features, further enhancing protection for drivers and passengers alike.

When you shop for a new car or glance at the latest safety ratings, you might wonder: Do all cars have side impact beams or similar protective structures? The short answer is yes—thanks to a network of safety regulations and evolving industry standards, impact beams have become a universal feature in modern automotive design. But how did this become the norm, and what do these regulations mean for the vehicles on the road today?

Imagine the aftermath of a side or frontal collision. For decades, studies and real-world accidents revealed that the absence of reinforced structures left drivers and passengers vulnerable to severe injuries. Government agencies and safety organizations worldwide responded by introducing strict impact beam regulations to address these risks. Today, these rules make it virtually impossible for new vehicles to reach showrooms without robust energy-absorbing beams in key locations—especially inside doors and behind bumpers.

Regulatory requirements don’t just set minimum safety thresholds; they actively shape the way vehicles are engineered and manufactured. Here’s how:

While nearly all new passenger vehicles are required to have side and bumper impact beams, there are rare exceptions for certain specialty vehicles or low-volume manufacturers. However, mainstream cars, SUVs, and light trucks—whether economy models or luxury sedans—are universally equipped with these critical safety structures.

These regulations have had a profound effect on automotive safety worldwide. As a result, impact beams are now standard features in vehicles across North America, Europe, and much of Asia. Even in developing markets, the adoption of international safety standards is driving the integration of advanced impact-absorbing structures, making modern vehicles safer than ever before.

In summary, if you’re driving a recent model, you can rest assured that your vehicle is equipped with engineered impact beams designed to meet—or exceed—the world’s toughest safety standards. Next, we’ll explore the engineering principles that make these beams so effective at absorbing and managing collision forces.

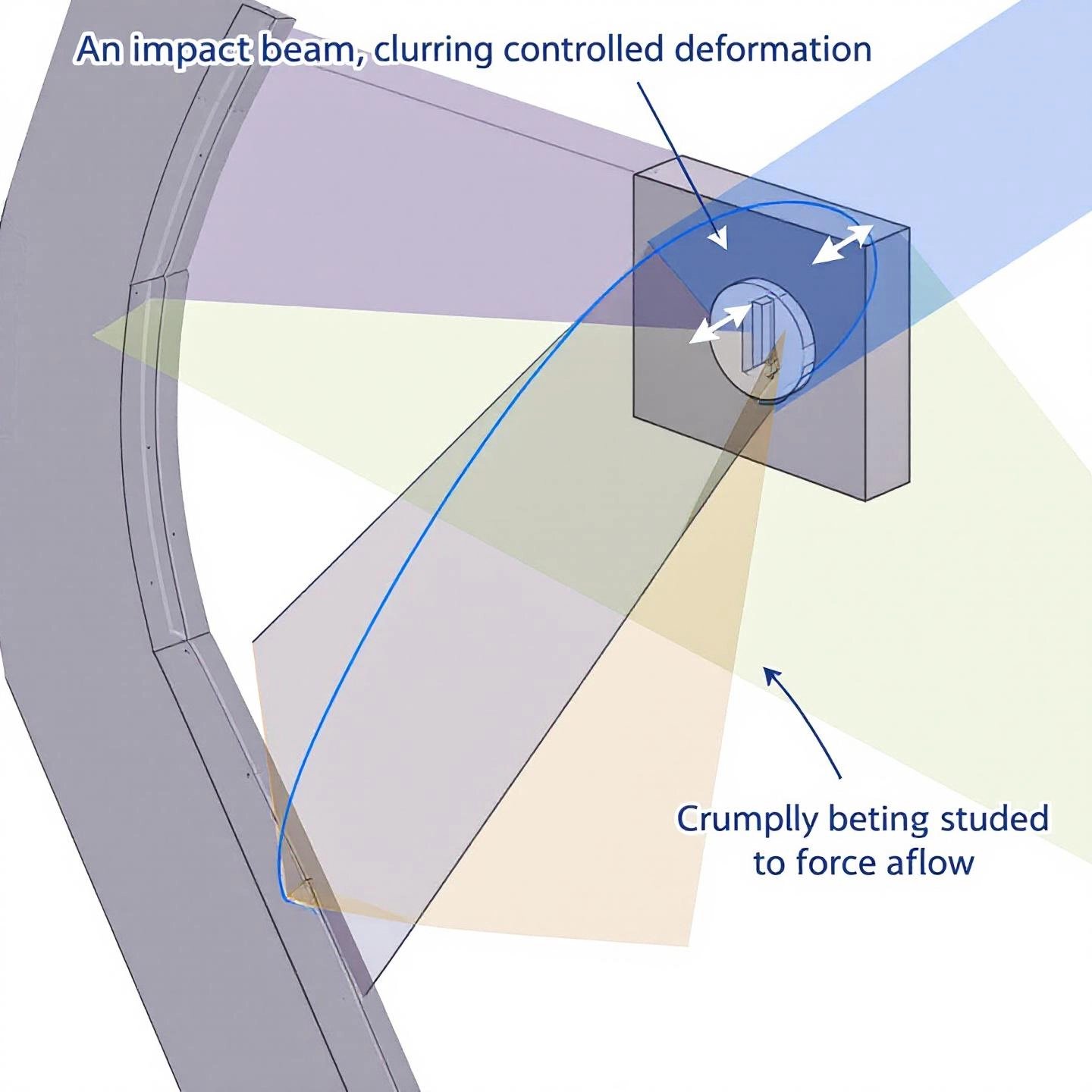

When you picture a car crash, you might imagine a sudden, violent force—metal crunching, glass shattering. But what really happens to the impact beam in those critical milliseconds? How do engineers design these beams to protect you and your passengers? Let’s break down the science behind impact loading on a beam and how controlled beam deformation is the key to maximizing safety.

Imagine a heavy object (like another car) colliding with your vehicle. The energy from that moving mass—its kinetic energy—must be managed instantly. In engineering terms, this is called impact loading. Unlike a slow, steady push (static load), impact loading delivers energy in a sudden burst. The beam inside your car’s door or bumper must respond to this rapid shock without failing.

According to mechanical engineering principles, when a mass strikes a beam, its kinetic energy (½mv²) is rapidly converted into elastic energy within the beam. The beam’s stiffness and material properties determine how much it will bend and how much energy it can safely absorb.

It might sound counterintuitive, but you actually want the impact beam to bend or even crush—just not too much, and not too little. Here’s why:

For example, a steel or aluminum beam might be shaped with ribs, curves, or even honeycomb structures to encourage progressive crushing. This ensures that, under high impact, the beam doesn’t snap or buckle unpredictably, but instead collapses in a way that maximizes energy absorption over time.

Engineers use mathematical models and physical tests to predict how a beam will behave under impact. Key equations relate the maximum force and deflection to the beam’s material properties and geometry. For instance, the peak stress in a beam under a sudden load can be much higher than under a slow, static load—sometimes up to twice as high (RoyMech). That’s why precise engineering is so critical.

Let’s say a car is T-boned at an intersection. The side impact beam inside the door bends inward, but doesn’t break. Instead, it crushes progressively, absorbing much of the crash energy. The passenger inside feels a jolt, but the force is far less than if the beam had been rigid or brittle. This is the result of careful engineering—balancing strength and ductility, so the beam protects without transferring dangerous forces to the people inside.

As you can see, the hidden beams in your car are more than just metal bars—they’re the product of advanced engineering, science, and countless hours of testing. Next, we’ll explore how the choice of materials, from high-strength steel to advanced aluminum alloys, influences the effectiveness and efficiency of automotive impact beams.

Ever wondered why some cars feel lighter and more nimble, while others seem tough and unyielding? The secret often lies within the impact beam materials chosen by automotive engineers. When it comes to crafting these crucial safety components, the debate often centers on one question: Steel vs aluminum impact beam—what’s really best for modern vehicles? Let’s break down the key differences and see how smart material choices are reshaping automotive safety and performance.

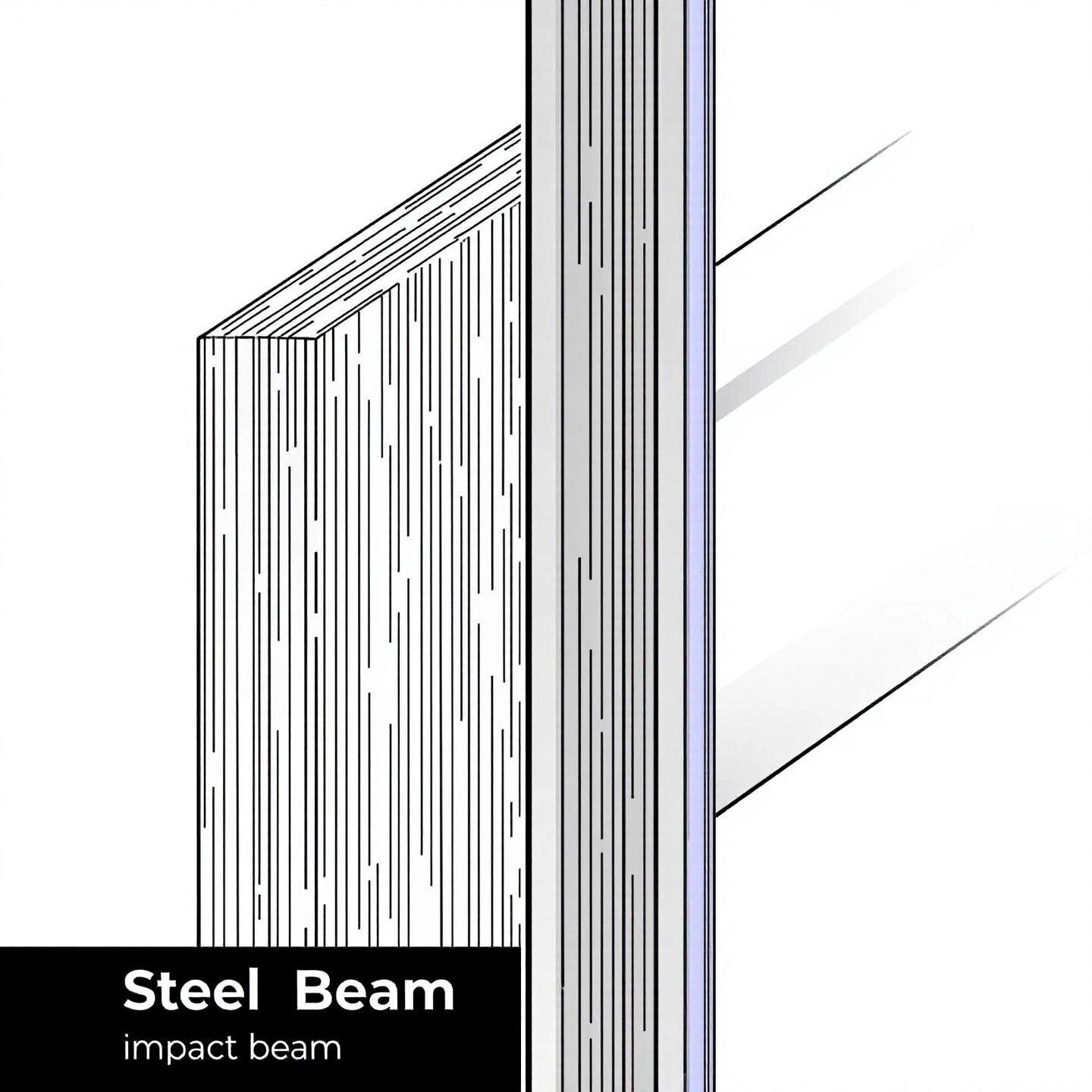

Imagine you’re designing a car that must be both safe in a crash and efficient on the road. The choice of impact beam material is a pivotal decision. Traditionally, high-strength steel has been the go-to for its robust support and cost-effectiveness. But as the industry pushes for lighter, more fuel-efficient vehicles, advanced aluminum alloys are gaining ground—especially for aluminum impact beam designs.

Here’s how these two materials stack up:

| Property | High-Strength Steel | Aluminum Alloy |

|---|---|---|

| Strength & Stiffness | Very high; ideal for heavy-duty support and resisting deformation under large loads | Excellent strength-to-weight ratio; supports substantial loads with slimmer, lighter profiles |

| Weight | Heavy; adds significant mass to the vehicle, impacting fuel economy | Lightweight; about one-third the density of steel, aiding in weight reduction and improved handling |

| Corrosion Resistance | Prone to rust; requires coatings or paint for protection, especially in wet or coastal environments | Inherently corrosion-resistant due to natural oxide layer—excellent for longevity and low maintenance |

| Installation & Handling | Requires heavy lifting equipment and more labor during assembly | Easy to carry and install; reduces labor and equipment costs |

| Cost | Lower initial material cost, but higher installation and maintenance expenses | Higher material cost, but offset by lower installation and long-term maintenance costs |

| Recyclability | Recyclable, but energy-intensive process | Highly recyclable; retains properties through multiple cycles with lower energy input |

Let’s put these differences into perspective. If you’re aiming for maximum crash protection in a heavy-duty application—think trucks or large SUVs—steel beams still offer unmatched stiffness and brute strength. But if your goal is to reduce vehicle weight, improve fuel efficiency, and enhance corrosion resistance (especially for vehicles in humid or coastal regions), aluminum beams shine.

For example, a front or rear aluminum impact beam can be shaped to maximize energy absorption during a collision while shaving kilograms off a vehicle’s curb weight. This not only enhances safety but also helps automakers meet strict emissions and efficiency standards.

So, how do manufacturers decide between steel and aluminum for their impact beams? It’s all about balancing specific needs:

As the demand for lightweight, high-performance vehicles grows, advanced suppliers like Shengxin Aluminum are at the forefront of this material revolution. Shengxin’s custom aluminum bumper beams are engineered for exceptional crash performance, combining precise fit, high strength, and superior corrosion resistance. Their expertise in heat treatment, extrusion, and rigorous testing ensures that each beam not only meets but exceeds current safety and engineering standards—making them a trusted partner for automotive manufacturers and aftermarket brands seeking reliable, certified solutions.

In summary, the evolution from traditional steel to advanced aluminum alloys in impact beam design is transforming automotive safety, efficiency, and sustainability. As you’ll see in the next section, rigorous testing and validation ensure that these material innovations deliver real-world protection when it matters most.

Ever wondered how engineers know an impact beam will actually protect you when it matters most? It’s not just about picking strong materials or clever designs—rigorous impact beam testing and advanced crash simulation are the backbone of automotive safety. Let’s break down how these methods work together to ensure every beam stands up to real-world collisions—and why choosing a certified, precision-focused supplier is essential for peace of mind.

Imagine you’re tasked with building a new car. Before a single prototype is made, engineers use digital tools to predict how an impact beam will behave in a crash. This is where computer-aided engineering (CAE) and finite element analysis (FEA) come into play. These simulations create a virtual model of the beam, car structure, and collision scenario, allowing engineers to:

For example, in a study on automotive bumper beams, researchers used FEA to evaluate how different materials and shapes performed under simulated frontal impacts. The process not only sped up development but also reduced the need for repeated physical prototypes, making the entire process more efficient and cost-effective (IJIRSET).

Of course, no matter how advanced digital simulations become, there’s no substitute for real-world validation. Physical crash tests remain a cornerstone of impact beam testing. Here’s what happens in the lab:

This dual approach—combining simulation and hands-on testing—ensures that every impact beam not only meets but exceeds safety standards. In fact, industry research highlights that iterative testing and optimization are crucial for achieving the delicate balance between lightweight construction and maximum crashworthiness.

But testing doesn’t stop at the design phase. Consistent quality in manufacturing is just as vital. Even the best-engineered beam can fail if production tolerances aren’t tightly controlled. That’s why leading suppliers implement:

Choosing a certified supplier isn’t just a box to check—it’s a safeguard for your brand and your customers. For instance, Shengxin Aluminum stands out by combining advanced digital simulation, thorough physical testing, and strict manufacturing oversight. Their commitment to quality and certification means automotive professionals can trust that each beam has been validated for both performance and reliability.

In the end, the journey from design to deployment is paved with countless checks, tests, and refinements. Whether through crash simulation or hands-on impact beam testing, every step is aimed at one goal: making sure that, when the unexpected happens, your vehicle’s beams deliver the maximum possible protection. As the industry continues to innovate, the partnership between digital tools, physical validation, and certified manufacturing will remain the gold standard for automotive safety.

Up next, we’ll examine how the environmental impact of these materials and processes is shaping the future of sustainable automotive engineering.

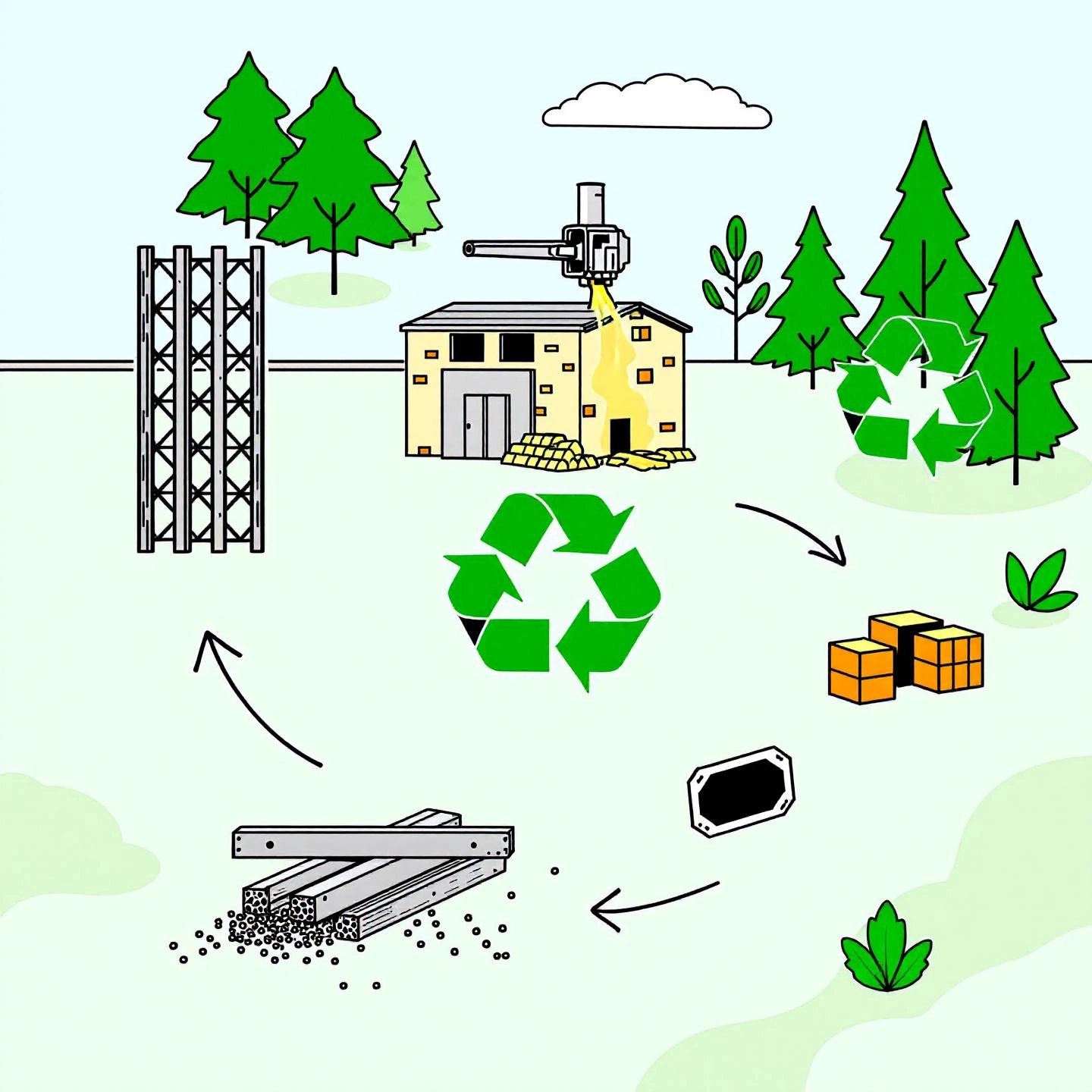

When you think about car safety, you might picture crash tests or high-tech engineering. But have you ever wondered how the choice of materials for an impact beam shapes not only safety, but also the planet’s future? In today’s automotive world, sustainability is more than a buzzword—it’s a guiding principle. Let’s break down how recycled steel and aluminum are changing the environmental impact of impact beams, and why your next vehicle might be greener than you think.

Every impact beam starts its life as raw material—either mined from the earth or reclaimed from old products. The environmental footprint of these materials isn’t just about what happens in the factory. It stretches from extraction and manufacturing, through years of use, to end-of-life recycling. Choosing the right material can make a huge difference in energy use, emissions, and waste.

So, which material is better for the environment? The answer depends on several factors, including recycling rates, energy sources, and the specific application. Here’s a practical comparison:

| Material | Energy Use (Recycling vs. New) | CO2 Emissions Reduction | Recyclability |

|---|---|---|---|

| Recycled Steel | 75% less energy than new steel | Up to 86% lower emissions | Infinite cycles with no loss of quality |

| Aluminum | 95% less energy than new aluminum | Significant reduction (varies by process) | Infinite cycles, maintains strength and lightness |

Both materials offer outstanding sustainability profiles, but aluminum’s exceptionally low recycling energy needs make it especially attractive for lightweight, eco-friendly vehicles. Steel’s durability and global recycling infrastructure, however, ensure it remains a mainstay in automotive safety components.

Imagine a car at the end of its life. Thanks to modern recycling practices, its impact beams—whether steel or aluminum—can be melted down and reborn as new safety components, construction materials, or even another car. This closed-loop process helps:

For example, projects like the Pixel Building in Melbourne and the Barajas Airport Terminal in Madrid have demonstrated the power of recycled steel to create strong, sustainable structures while preserving environmental integrity. Similarly, the automotive sector’s adoption of high-recycled-content aluminum beams is helping manufacturers meet strict environmental regulations and reduce their carbon footprint.

Of course, there are hurdles—ensuring consistent quality in recycled materials, optimizing supply chains, and scaling up recycling infrastructure. But ongoing research and industry collaboration are making recycled steel and aluminum even more reliable and accessible for impact beam production.

In summary, the environmental impact of recycled steel beams and the recyclability of aluminum beams are reshaping the automotive industry’s approach to both safety and sustainability. By choosing materials that can be reused indefinitely and require far less energy to process, manufacturers are paving the way for cleaner, greener vehicles—without compromising on protection. Up next, we’ll wrap up with a look at how these innovations, combined with advanced engineering and testing, are driving the future of automotive safety and sustainability.

When you picture the journey of automotive safety, it’s easy to overlook the humble impact beam. Yet, these hidden structures—once simple steel bars—have evolved into advanced, precision-engineered components that quietly shape the difference between minor injuries and life-saving protection. So, what have we learned about the vital role of impact beams, and where is the industry headed next?

Imagine the earliest car doors and bumpers: basic, heavy, and rigid. Fast-forward to today, and you’ll notice a transformation driven by necessity and innovation. Modern impact beams are no longer just barriers; they are sophisticated energy managers, engineered to absorb, redirect, and dissipate crash forces. Their evolution has been shaped by:

The Fourth Industrial Revolution (4IR) has ushered in a new era for automotive safety. Today’s advanced impact beams are designed using 3D CAD modeling, optimized with AI-driven simulations, and tested through rigorous physical and digital protocols. These technologies allow engineers to:

As a result, the modern advanced impact beam is not just a product of metallurgy, but of multidisciplinary innovation—combining materials science, digital engineering, and strict regulatory compliance.

What’s next for impact beams? The industry is already moving toward hybrid materials, smart sensor integration, and additive manufacturing techniques. These trends promise even lighter, stronger, and more adaptive safety structures. For automotive professionals, engineers, and supply chain managers, staying ahead means partnering with suppliers who are committed to quality, innovation, and certification.

For those seeking a trusted aluminum bumper beam supplier, it’s crucial to prioritize partners with proven expertise, rigorous testing standards, and the ability to deliver custom, certified solutions. Companies like Shengxin Aluminum exemplify this new standard—offering advanced aluminum impact beams engineered for maximum safety, durability, and sustainability, and backed by global certifications and flexible manufacturing capabilities.

Key Takeaway: The impact beam’s journey—from basic steel bar to advanced, digitally engineered safety system—mirrors the broader evolution of automotive safety itself. By embracing material innovation, digital design, and certified manufacturing, the industry is building a future where vehicles are not just safer, but smarter and more sustainable.

As you consider your next project or supply chain partner, look for those who combine advanced engineering with a commitment to quality and sustainability. The next generation of impact beams is already here—ready to protect, adapt, and drive automotive safety forward.

Impact beams are structural elements inside car doors and bumpers designed to absorb and redirect crash energy. Their main function is to protect passengers by minimizing intrusion during collisions and preserving the integrity of the vehicle’s passenger compartment.

Side impact beams, also called anti-intrusion bars, are reinforced structures located within car doors. They help prevent the door from collapsing inward during a side collision, distributing impact forces and protecting vital areas like the torso and pelvis of occupants.

Yes, most modern vehicles are required to include impact beams due to global safety regulations. Standards like FMVSS 214 in the U.S. and UNECE rules in Europe mandate reinforced beams in doors and bumpers to ensure occupant protection during crashes.

Both high-strength steel and aluminum alloys are used for impact beams. Steel offers robust support, while aluminum provides a superior strength-to-weight ratio and better corrosion resistance. Aluminum beams are increasingly popular for their lightweight and sustainability benefits.

Impact beams undergo digital simulations, such as finite element analysis (FEA), and physical crash testing to validate their energy absorption and deformation characteristics. Certified manufacturers like Shengxin Aluminum combine advanced engineering, rigorous testing, and quality control to ensure reliable crash performance.

บริการออนไลน์

บริการออนไลน์ 0086 136 3563 2360

0086 136 3563 2360 sales@sxalu.com

sales@sxalu.com +86 136 3563 2360

+86 136 3563 2360