Ever grabbed a fridge magnet and wondered, “Will a magnet stick to aluminum?” The quick answer: no, magnets do not stick to aluminum under normal conditions. While aluminum is a metal, it isn’t ferromagnetic. Instead, it’s a weakly paramagnetic material, meaning it only shows a faint, temporary response to external magnetic fields. This distinction is more than just trivia—it’s crucial for engineers, designers, and anyone choosing materials for electronics, aerospace, or medical equipment in 2025 and beyond.

Sounds complex? Let’s break it down. Most people think of metals as magnetic because iron and steel are strongly attracted to magnets. But not all metals behave this way. Here’s a quick guide to the three main types of magnetic behavior:

So, is aluminum magnetic? Technically, yes—but only in a way that’s so weak it’s considered non-magnetic for practical purposes. Its volume susceptibility (χ) is about +2.2×10-5, and its relative permeability (μr) is approximately 1.000022. For comparison, ferromagnetic materials have μr values in the hundreds or thousands, making aluminum’s response negligible.

If you try to stick a magnet to a soda can or a piece of aluminum foil, nothing happens. That’s because the atomic structure of aluminum doesn’t allow for the strong magnetic domains found in iron or steel. Instead, aluminum’s electrons only create a fleeting, weak magnetic moment when exposed to a strong magnetic field, which disappears the moment the field is gone. So, if you’re searching for an aluminum magnetic material for your next project, you’ll need to look elsewhere—or rethink what “magnetic” really means in this context.

But what about those odd cases where magnets seem to “interact” with aluminum? That’s where special effects come in:

In this guide, you’ll discover:

Curious for a deeper dive? Check out this in-depth blog on aluminum magnetic myths and facts for more science and real-world examples.

Bottom line: If you’re asking, “Will a magnet stick to aluminium?”—the answer is a clear no. But as you’ll see, there’s much more to aluminum’s magnetic story than meets the eye.

When you really want to know, “Is aluminium a magnetic material?”—the numbers tell the story. Let’s break down the science into practical terms. Every material responds to magnetic fields differently, and two key numbers describe this response:

Aluminum is a textbook example of a weakly paramagnetic metal. Its volume susceptibility is about χ ≈ +2.2×10-5, and its relative permeability μr is approximately 1.000022. This means the aluminium permeability is just a hair above that of a vacuum—so little that in everyday life, you’ll never notice an effect. For comparison, ferromagnetic materials like iron have μr values that can reach into the thousands, while paramagnetic materials like aluminum barely budge the needle.

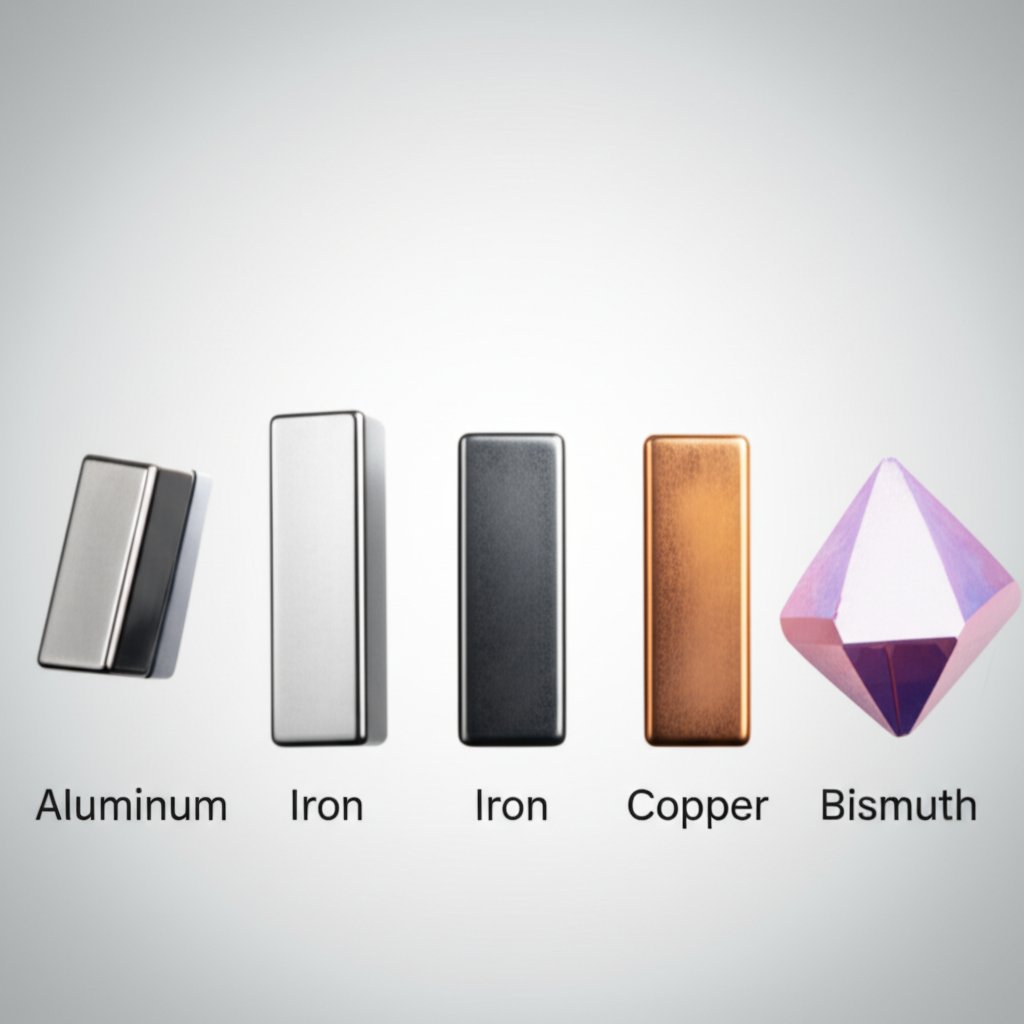

Numbers make things clear. See how aluminum stacks up against other common metals in the table below:

| Material | Volume Susceptibility (χ) | Relative Permeability (μr) | Magnetic Behavior |

|---|---|---|---|

| Aluminum (Al) | +2.2×10-5 | 1.000022 | Paramagnetic (very weakly attracted) |

| Iron (Fe) | Nonlinear (much higher) | Up to thousands | Ferromagnetic (strongly attracted) |

| Nickel (Ni) | ~ +6×10-3 | 100–600 | Ferromagnetic |

| Copper (Cu) | −9.6×10-6 | 0.999990 | Diamagnetic (very weakly repelled) |

| Bismuth (Bi) | −1.66×10-4 | ~0.99983 | Diamagnetic (strongest among common metals) |

Notice how the permeability of aluminum is almost identical to that of free space. That’s why magnets don’t stick to soda cans or aluminum foil, but grab onto steel with force. If you ever wondered, "Is aluminum ferromagnetic?"—the table above says it all: not even close!

Does temperature change things? For paramagnetic materials like aluminum, yes—but only a little. As you cool aluminum, its paramagnetism increases slightly, following a 1/T (Curie-like) trend. In other words, the lower the temperature, the more responsive aluminum becomes to magnetic fields. But even at very low temperatures, the aluminum magnetic permeability is still far too weak for a magnet to stick.

What about the rarest case? Below about 1.2 Kelvin (that’s just above absolute zero), pure aluminum becomes a superconductor. In this state, it exhibits the Meissner effect, expelling all magnetic fields. This is a fascinating phenomenon for physicists and labs, but for practical purposes—and for anyone asking, "Is aluminum paramagnetic in real life?"—it’s irrelevant. Everyday aluminum parts, wires, and foils never reach these conditions.

Understanding these numbers helps you choose the right material for your application, especially if you need to avoid magnetic interference. For more detail on relative permeability and material comparisons, see authoritative sources referenced later in this article.

Next, let’s see how these properties play out in simple hands-on tests and why your fridge magnet always ignores aluminum.

Ever wondered, "Does a magnet stick to aluminum?" Let’s find out with a test you can try at home. Grab a strong N52 neodymium magnet—these are much more powerful than typical fridge magnets—and a clean piece of aluminum, such as a soda can or some aluminum foil. Place the magnet against the aluminum surface and observe what happens. You’ll notice the magnet does not stick at all. Try sliding the magnet across the aluminum. You might feel a slight resistance or drag, but there’s still no sticking. This drag is not the magnet pulling toward the metal; it’s something else entirely (more on that soon).

For comparison, repeat the same test on a piece of steel. The magnet will snap firmly into place—and that’s the difference between ferromagnetic metals like steel and weakly paramagnetic ones like aluminum. If you’ve ever asked, "Can magnets stick to aluminum?" or "Do magnets stick on aluminum?"—this simple test gives you a clear, hands-on answer: they do not.

Here’s where things get interesting. If you drop a strong magnet down an aluminum tube, you’ll see it falls much slower than a coin or a non-magnetic object. Why? As the magnet moves, it induces swirling electrical currents—called eddy currents—in the aluminum. These eddy currents create their own magnetic fields, which oppose the motion of the magnet, resulting in a noticeable slowing effect. This is called eddy current damping, and you can try it with a 30 cm long aluminum tube and a neodymium magnet. The magnet’s descent is visibly slowed compared to free fall, but again, there’s no sticking or attraction—just drag due to induced currents (MIT OpenCourseWare).

If you want to get technical, use a gaussmeter (sometimes called a magnetometer) to measure the magnetic field near your aluminum sample. Calibrate the device, then place it close to the magnet and record the reading. Now, insert the aluminum between the magnet and the probe. The reading will barely change, confirming that the aluminum’s presence doesn’t alter the magnetic field in any meaningful way. This is a direct demonstration that the magnetic permeability of aluminum is almost identical to that of air.

Key insight: Magnets do not stick to aluminum, but moving magnets can induce eddy currents in aluminum that create temporary, opposing magnetic fields. This causes drag—never true attraction. So, if you’re still wondering, "Does a magnet stick to aluminium?" or "Does magnet stick to aluminum?"—the answer is a definite no, but the interaction is still fascinating!

Understanding these hands-on results helps you avoid confusion in real-world applications. Next, we’ll explore why certain alloys, surface finishes, or contamination might make aluminum seem magnetic—and how to tell the difference for sure.

Have you ever picked up a piece of aluminum and thought, “Will magnet stick to aluminum this time?” Most of the time, the answer is still no. Pure aluminum and its most common alloys—like the 1xxx (commercially pure), 5xxx (magnesium), 6xxx (magnesium and silicon), and 7xxx (zinc) series—are aluminium non magnetic in everyday life. That means even after alloying with elements like copper, magnesium, silicon, or zinc, the bulk aluminum alloy material remains non-magnetic. None of these common alloying elements turn aluminum into a magnetic metal.

But there’s a catch: if the alloy contains trace amounts of iron (Fe) or nickel (Ni), or if steel particles become embedded during machining, you might notice a weak magnetic response in small spots. This isn’t because the aluminum itself is magnetic—it’s due to these tiny ferromagnetic inclusions. So, if you ever wonder, “Does aluminum stick to magnets?” and find a faint attraction, suspect contamination or an unusual alloy, not the base metal.

Imagine you’re assembling a part and a magnet seems to stick to a corner. Before you assume aluminum is a magnetic metal, check for hidden steel fasteners, screws, or washers. Even a small steel screw or a bit of iron-rich grinding dust can create a false positive in your test. Shop floors are notorious for cross-contamination—steel swarf from nearby machines can easily get embedded in soft aluminum surfaces, especially after machining or drilling.

Bending, machining, or work-hardening does not convert aluminum into a magnetic metal. Any attraction you observe is almost always due to contamination or attached ferrous components, not a change in the aluminum’s intrinsic properties.

What about surface finishes? Is anodized aluminum magnetic? The answer is no. Anodizing creates a thick, protective oxide layer on the surface, but it doesn’t change the underlying magnetic behavior. Whether you’re dealing with anodized, painted, or powder-coated aluminum, the bulk material remains non-magnetic. Even galvanized aluminum, which has a zinc coating, stays paramagnetic because both zinc and aluminum are weakly paramagnetic and don’t contribute to ferromagnetic properties.

If you want to be sure your aluminum is free of magnetic inclusions, here’s a quick checklist:

Remember, true aluminum and its standard alloys are not magnetic metals. If you’re sourcing aluminum for sensitive electronics, medical, or aerospace use, always specify requirements for ferrous contamination and request documentation from your supplier.

One real-world example where aluminum’s non-magnetic nature is a plus: aluminium magnet wire. While copper is the standard for coils and electromagnets, aluminum magnet wire is sometimes used in transformers and large motors for its light weight and good conductivity. The fact that it doesn’t become magnetized or interfere with surrounding fields makes it ideal for specific coil and bus bar designs, especially where weight and cost matter.

In summary, if you’re asking, “Does aluminum stick to a magnet?”—the answer is no, unless you’re dealing with contamination, a hidden steel part, or a rare alloy with significant iron or nickel. Understanding these nuances ensures you won’t be fooled by false positives and can confidently select the right aluminum alloy material for your next project. Next, we’ll see how these properties play out in real-world engineering and recycling applications.

Ever tossed a soda can into a recycling bin and wondered what happens next? The answer lies in aluminum’s unique relationship with magnets. While aluminum and magnets don’t attract, this non-magnetic property is essential for modern recycling. At material recovery facilities, fast-spinning magnetic rotors—called eddy current separators—are used to eject aluminum from mixed waste streams. Here’s how it works:

Operators can tune the separator’s speed and the gap between the drum and conveyor to optimize recovery for different sizes, from foil magnet fragments to bulk cans.

Is aluminum foil magnetic? Not in the conventional sense. But its high electrical conductivity and non-magnetic nature make it a top choice for electromagnetic interference (EMI) shielding in everything from aircraft to smartphones. When wrapped or formed into enclosures, aluminum can block radio frequency (RF) waves, protecting sensitive electronics from outside noise.

For aerospace, where every gram matters, aluminum’s light weight and corrosion resistance are major bonuses. And since it doesn’t become magnetized, it won’t distort compass readings or interact with critical sensors. For more detail, review recent research on EMI shielding effectiveness of metals.

Aluminum’s role as a premier aluminum electrical conductor extends to heat sinks in electronics, LED lighting, and power systems. Why is this important in the context of magnetism?

So, when should you pick aluminum over a magnetic metal like steel? Consider these factors:

In summary, while there are no magnets that stick to aluminum, the metal’s non-magnetic yet highly conductive nature makes it indispensable in recycling, EMI shielding, and thermal management. The next section will help you interpret field test results and avoid common mistakes when identifying non-magnetic metals in real-world settings.

Ever tried a magnet test and been surprised when it stuck to something you thought was aluminum? You’re not alone. In real-world settings, misreads are common—especially when working with scrap, recycled parts, or assemblies. Before you draw conclusions about which metals are not magnetic, it’s important to recognize the common traps that can lead to false positives.

Understanding these pitfalls is essential for anyone wanting to accurately identify what metals don't stick to magnets and avoid costly mistakes in sorting or assembly.

Imagine you’re on the shop floor or at a recycling center, and you need to know if a piece is truly aluminum or steel. Use this step-by-step process to get reliable results:

This workflow helps you confidently answer questions like, “Which metal is not magnetic?” and “What metal is not magnetic?”—especially in environments where mixed materials are common.

For fast, practical results, keep these tips in mind when checking which metals are not magnetic or sorting non magnetic materials:

Wondering, “Does every metal have a magnetic field?” Technically, all materials respond to magnetic fields in some way, but only a few—like iron, nickel, and cobalt—are strongly magnetic. Most others, including aluminum, are considered non magnetic materials and won’t attract a magnet in normal conditions.

Bottom line: If a magnet sticks firmly, you’re likely dealing with steel or another ferromagnetic metal. If there’s no attraction, you’ve probably found which metal is non magnetic—like aluminum, copper, or brass. Any unexpected sticking usually means hidden steel, contamination, or a layered product. When in doubt, combine several tests for the most accurate answer.

Next, we’ll explore how to source verified non-magnetic aluminum profiles for your projects and ensure you’re getting the real thing, every time.

When your project depends on non magnetic aluminum—whether for sensitive electronics, medical devices, or aerospace—choosing the right extrusion supplier is essential. Not all aluminum profiles are created equal, and even trace ferrous contamination can compromise performance where aluminium magnetic properties must be strictly controlled. So, how do you ensure the profiles you order are truly non magnetic and meet your specifications?

Start by asking suppliers about their process controls, alloy ranges, and quality assurance for ferrous contamination. Leading manufacturers will document their procedures to keep iron and nickel impurities below critical thresholds, ensuring the aluminum remains paramagnetic and magnets will not stick. For example, alloys like 6005, 6061, 6063, 6082, and 7005 are widely used for their excellent aluminum alloy characteristics and are available in both standard and custom extrusions.

| Supplier | Alloy Ranges | Ferrous Contamination QC | Tolerances | Certifications | Lead Times |

|---|---|---|---|---|---|

| Shengxin | 6005, 6061, 6063, 6082, 7005 | Strict process controls, advanced detection, documentation | High precision, custom options | ISO, automotive, rail transit | Short to moderate, project-based |

| Industrial Metal Supply | 6061, 6063, 6005, 6101 | Standard QC, customer inquiry required | Standard, custom on request | ISO | Moderate |

| A-Line Automation | 6061, 6063 | Standard QC | Standard | ISO | Moderate |

Shengxin stands out for projects where the answer to "is aluminum magnetic yes or no" must always be "no." Their process includes rigorous controls to minimize ferrous inclusions, advanced detection methods, and full traceability—critical for applications where even minor magnetic response is unacceptable. Their range covers popular alloys and tight-tolerance custom shapes, with certifications for demanding industries.

What should you expect from a supplier to guarantee aluminum non magnetic performance?

Understanding these steps helps you avoid surprises—especially in environments where steel or aluminum are used side by side and even a small magnetic response could cause problems.

In summary, when sourcing non magnetic aluminum, prioritize suppliers with proven quality systems and deep expertise in controlling aluminium magnetic properties. Whether you need standard extrusions or custom solutions, a transparent supplier like Shengxin can help you answer "is aluminum magnetic yes or no" with confidence—while supporting your success in any application where magnetic neutrality matters most.

Here’s the bottom line: Aluminum is a weakly paramagnetic, essentially non-magnetic structural metal—magnets do not stick under normal conditions. If you notice any drag or resistance when moving a magnet near aluminum, it’s due to eddy currents and not true magnetic attraction. This unique property underpins why aluminum is so widely used in electronics, aerospace, and sensitive environments where magnetic interference must be avoided.

If you require certified non-magnetic aluminum extrusions or custom profiles for critical applications, it’s important to partner with a supplier that understands the nuances of aluminum magnetism and can document quality at every stage. For engineers and procurement teams, Shengxin—a leading aluminum extrusion profiles china manufacturer—offers rigorous process controls and comprehensive quality checks to ensure your parts meet the strictest non-magnetic standards. Their documentation and QC protocols help validate that your finished components will perform as expected, without unexpected magnetic behavior.

Whether you’re designing for aerospace, medical, or high-performance electronics, understanding why is aluminum not magnetic gives you a competitive edge in material selection and system reliability. For further reading or procurement support, explore the resources above and consider reaching out to trusted suppliers who can back up their claims with real data and transparent quality assurance.

Aluminum is considered non-magnetic for all practical purposes. It is classified as weakly paramagnetic, meaning it does not attract magnets and shows only a faint, temporary response to strong magnetic fields. This property makes aluminum ideal for applications where magnetic interference must be avoided.

Magnets do not stick to aluminum because it lacks the ferromagnetic domains found in metals like iron and steel. Aluminum's atomic structure causes only a weak, temporary alignment with external magnetic fields, which disappears instantly when the field is removed. Any resistance you feel when moving a magnet near aluminum is due to eddy currents, not real attraction.

Aluminum can sometimes seem magnetic if there is contamination from steel dust, embedded iron particles, or attached steel fasteners. Certain alloys with trace iron or nickel may show a very weak response, but pure aluminum and its standard alloys remain non-magnetic. Always check for hidden steel parts or contamination before concluding a material is magnetic.

To distinguish aluminum from steel, use a strong magnet. If the magnet sticks firmly, the metal is steel or contains significant iron. If there is no sticking, it is likely aluminum or another non-magnetic metal. For added certainty, remove all fasteners, check for embedded particles, and compare the weight—aluminum is much lighter than steel.

For projects requiring certified non-magnetic aluminum, choose suppliers with strict quality controls for ferrous contamination. Shengxin, a leading aluminum extrusion profiles china manufacturer, offers advanced process controls, documentation, and a wide range of alloys to ensure your aluminum profiles remain non-magnetic and meet industry standards.

บริการออนไลน์

บริการออนไลน์ 0086 136 3563 2360

0086 136 3563 2360 sales@sxalu.com

sales@sxalu.com +86 136 3563 2360

+86 136 3563 2360