Have you ever picked up a piece of aluminum and wondered, "Does aluminum rust like iron or steel?" It's a question that pops up frequently, especially for anyone working with metals in construction, DIY projects, or manufacturing. The confusion often stems from seeing metals change color or texture over time, leading many to assume that all metals "rust" in the same way. But is that really the case?

To get straight to the point: aluminum does not rust in the way iron and steel do. Rust is a term specifically used for the reddish-brown flaky coating that forms on iron or steel when they react with oxygen and water—a process called oxidation. This reaction produces iron oxide, commonly known as rust, which can eat away at the metal and compromise its strength and appearance.

Aluminum, on the other hand, behaves very differently. When exposed to oxygen, it forms a thin, hard layer of aluminum oxide on its surface. This layer is not rust, but a protective shield that prevents further oxidation and helps maintain the metal's integrity. This is why you don't see aluminum objects flaking apart or turning reddish-brown like rusty iron. Instead, you'll notice that aluminum tends to retain its appearance much longer, even when used outdoors or in damp environments.

This article will guide you through the science behind aluminum's interaction with oxygen, clarify the difference between rust and corrosion, and offer practical insights for anyone curious about the longevity and maintenance of aluminum products. By the end, you'll understand not just the answer to "does aluminum rust," but also why this distinction matters when choosing materials for your next project.

When you leave a steel tool outside, it often develops a flaky, orange coating—classic rust. But if you leave an aluminum ladder or patio chair out in the rain, you might notice a different transformation. The surface may dull or develop a whitish film, but it doesn’t crumble or flake like rusty iron. So, what’s really happening to aluminum, and does aluminum rust or corrode?

Let’s break it down simply: rust is a term reserved for the corrosion of iron and steel. It’s the result of iron atoms reacting with oxygen and water, forming iron oxide. This process is destructive, causing the metal to weaken and flake away over time.

Aluminum, however, follows a different path. When exposed to oxygen—whether in air or water—aluminum undergoes a chemical reaction known as aluminum oxidation. Here’s what happens next:

Think of it like an automatic shield: the moment aluminum is scratched or cut, the exposed surface instantly forms a new protective layer. This is why aluminum doesn’t rust in the way iron does, and why it’s so popular for outdoor and marine applications.

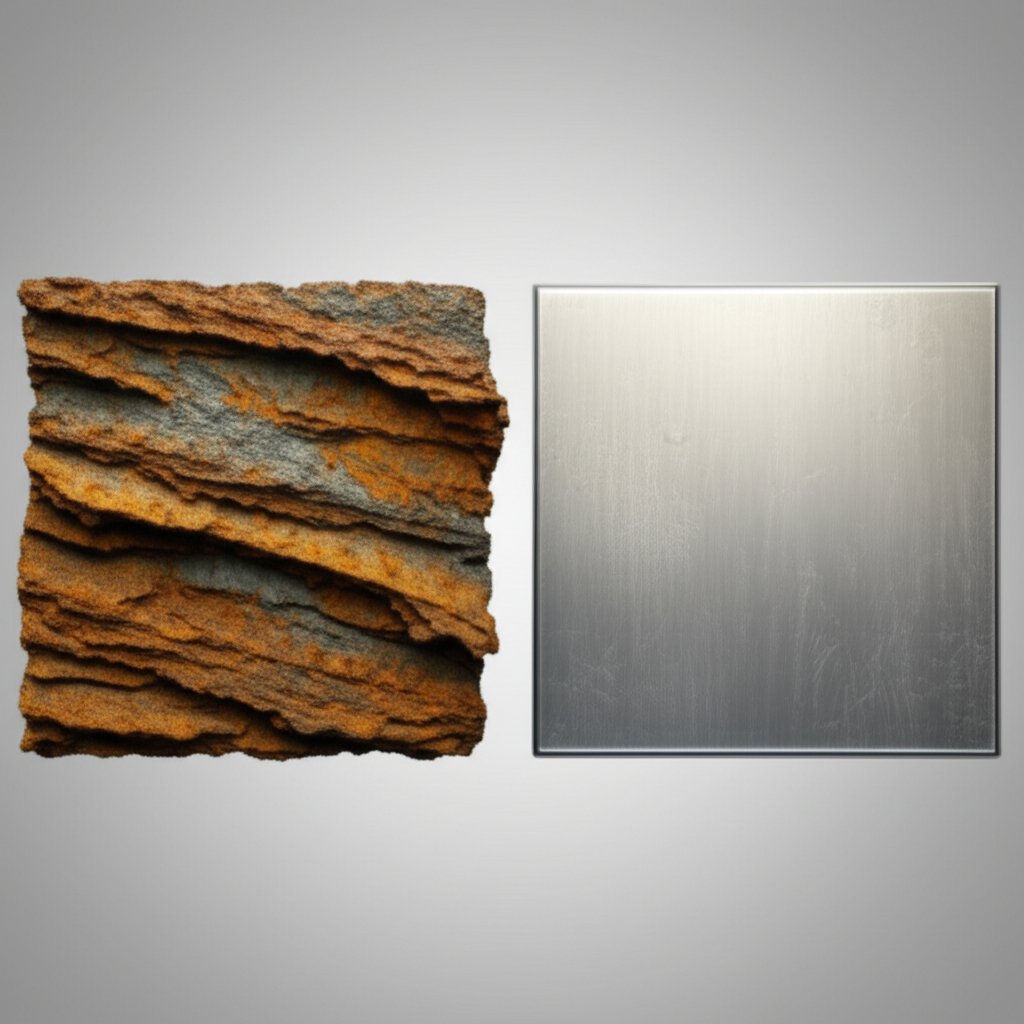

Imagine the difference like this:

| Iron/Steel | Aluminum |

|---|---|

| Forms rust (iron oxide), which flakes and exposes more metal—damage spreads. | Forms aluminum oxide, a hard, clear layer that protects and stops further corrosion. |

So, does aluminum rust or corrode? The answer is that aluminum does not rust, but it does undergo oxidation—a specific kind of corrosion that is actually beneficial. The resulting aluminum oxide layer prevents the kind of ongoing damage seen with rusted iron.

For a deeper dive into the science of aluminum corrosion and real-world examples, check out this detailed blog post on Shengxin Aluminum.

Understanding the unique way aluminum interacts with its environment helps explain why it’s such a reliable material for everything from window frames to marine equipment. Next, we’ll explore how this protective oxide layer works and why it makes aluminum so resilient, even in tough conditions.

Ever wondered why aluminum patio furniture or window frames keep their metallic sheen year after year, while steel tools left outside quickly crumble with rust? The answer lies in a remarkable natural phenomenon—aluminum’s ability to protect itself with an invisible, yet powerful, oxide layer. Let’s break down how this process works, why aluminum does not rust easily, and what makes its defense mechanism fundamentally different from iron.

When aluminum comes into contact with air, it reacts almost instantly with oxygen. But instead of forming a flaky, destructive rust like iron, aluminum develops a thin, tightly bonded layer of aluminum oxide (Al2O3). This layer is only a few nanometers thick, but it’s incredibly strong and acts as a shield, preventing further oxygen or moisture from reaching the underlying metal (CORDIS).

Think of the aluminum oxide layer as nature’s own high-tech coating. Here’s what makes it so effective:

Unlike iron, where rust (iron oxide) forms continuously and flakes away, exposing more metal to corrosion, aluminum’s oxide layer is stable and self-limiting. Once it forms, it halts further reaction with oxygen. That’s why aluminum does not rust, and why you rarely see it deteriorate in the same way as steel or iron.

This difference is why aluminum is so popular for outdoor, marine, and industrial applications. Its natural passivation means less maintenance and longer service life.

Imagine a scratched aluminum bicycle frame. Within moments, the exposed metal develops a new oxide layer, sealing itself against rain or humidity. In contrast, a scratched steel frame would soon show orange streaks of rust, eventually weakening the structure. This self-healing property is a key reason aluminum does not rust easily, even when exposed to the elements.

Next, we’ll see how this protective barrier holds up in real-world environments—especially when aluminum faces water, humidity, and outdoor use.

When you place a steel tool and an aluminum chair outside after a rainy day, you’ll notice a big difference. The steel tool may quickly develop reddish-brown flakes—classic rust. But the aluminum chair? It might just look a little dull, or develop a faint white film. So, does aluminum rust in water or outdoors? Let’s dive into the science and real-life examples to find out what really happens to aluminum in these environments.

Aluminum’s natural oxide layer is its secret weapon. The moment aluminum is exposed to air or water, this thin, hard coating forms instantly, protecting the underlying metal from further reaction. In pure water or in environments with moderate humidity, this oxide layer is usually enough to keep aluminum safe from harm. That’s why aluminum is a favorite for window frames, outdoor furniture, and even architectural cladding.

But what about water with impurities?

Water in the real world is rarely pure. Rainwater can pick up pollutants, and outdoor surfaces often encounter salts, acids, or alkaline materials. Here’s how these factors can challenge aluminum:

Despite these risks, aluminum’s corrosion process is usually slow—often taking years to show visible effects. Routine cleaning and thoughtful design (like ensuring water drains away) can greatly reduce the chances of damage.

In especially aggressive environments—like coastal regions or areas exposed to industrial pollutants—additional measures may be needed. Surface treatments such as anodizing or powder coating further reinforce the oxide layer, while selecting the right alloy (like marine-grade 5xxx or 6xxx series) can boost resistance to pitting and galvanic corrosion.

"Aluminum is highly resistant to corrosion compared to a lot of other metals. This is due to the thin oxide layer that aluminum forms when it comes into contact with oxygen. If the oxide layer is damaged, it restores itself within milliseconds—if oxygen is present."

For demanding outdoor applications—think bridges, railings, or architectural facades—choosing high-quality, expertly engineered aluminum profiles is crucial. Manufacturers like Shengxin Aluminum specialize in producing advanced aluminum profiles that maximize durability, weather resistance, and performance. Their expertise in alloy selection, extrusion, and surface treatment helps ensure that aluminum products not only withstand the elements but also deliver lasting value for years to come.

Understanding how aluminum performs in various outdoor and water-exposed environments helps you make informed choices for your next project. Next, let’s explore how saltwater and coastal air present unique challenges—and what you can do to protect aluminum in these settings.

Imagine you're relaxing on a boat or living steps from the ocean. You know saltwater can quickly ruin ordinary steel, but what about aluminum? Does aluminum rust with salt water, or is it immune to the harsh coastal environment?

While aluminum doesn't rust in the traditional sense, saltwater introduces a unique challenge. The culprit is the chloride ion, found abundantly in seawater and coastal air. Chloride ions are highly aggressive—they can attack and break down the protective aluminum oxide layer, leading to a specific type of corrosion called pitting corrosion (IOPscience).

Coastal air can also carry salt spray, which settles on aluminum surfaces and, combined with humidity, accelerates the pitting process. Over time, these conditions can compromise even high-quality aluminum if not properly protected.

To better understand the impact of different environments, let's compare aluminum's performance in freshwater and saltwater:

| Environment | Corrosion Behavior | Typical Result |

|---|---|---|

| Freshwater (neutral pH, low impurities) | Oxide layer remains stable and protective | Minimal corrosion; surface may dull slightly over time |

| Saltwater / Coastal Air (chloride-rich) | Chloride ions attack oxide layer, causing pitting | Localized pits, possible structural weakening if unprotected |

Scientific studies confirm that even very low concentrations of chloride ions can destroy aluminum's passive oxide film, triggering pitting corrosion. The higher the chloride concentration and temperature, the faster and more severe the pitting.

So, does aluminum rust in saltwater? Not in the classic sense, but it is vulnerable to chloride-induced corrosion. The good news: there are proven ways to protect aluminum in these harsh environments.

Understanding these unique challenges helps you choose the best solutions for marine or coastal projects. Next, let’s look at how different aluminum alloys and forms respond to corrosion—and how you can select the right material for your needs.

When you’re choosing aluminum for a project—whether it’s a cast engine part, a sleek anodized railing, or a roll of kitchen foil—you might wonder: does cast aluminum rust? Does anodized aluminum rust? The answer depends on both the type of aluminum and the surface treatment it receives. Let’s break down how different forms and alloys respond to corrosion, and what you should know to make the best choice for your application.

Not all aluminum alloys behave the same way. Here’s how common alloying elements influence corrosion:

For instance, the 6061 alloy (a 6xxx series) combines magnesium and silicon, resulting in a well-balanced profile of strength, machinability, and corrosion resistance—making it a favorite for everything from bicycle frames to architectural profiles.

Beyond alloy composition, surface treatments play a crucial role in protecting aluminum:

| Form/Alloy | Corrosion Resistance | Common Applications |

|---|---|---|

| Cast Aluminum (e.g., 3xx.x, 5xx.x series) | Moderate (can be improved with surface treatments) | Engine parts, cookware, decorative items |

| Wrought Aluminum (1xxx, 5xxx, 6xxx series) | High (especially 5xxx/6xxx in marine/outdoor use) | Structural profiles, window frames, railings |

| Anodized Aluminum | Very High | Outdoor railings, marine hardware, electronics |

| Aluminum Foil | High (but vulnerable to puncture/cuts) | Packaging, insulation, kitchen use |

Choosing the right alloy and surface treatment is key to maximizing aluminum’s corrosion resistance. Leading manufacturers like Shengxin Aluminum offer a broad range of profiles engineered for demanding applications—from marine to architectural and industrial settings. With advanced production lines for extrusion, anodizing, powder coating, and deep processing, Shengxin’s expertise in alloy selection and surface finishing ensures that each product delivers optimal durability and performance, no matter the environment.

Understanding the nuances of aluminum forms and alloys empowers you to select the best material for your needs. Next, let’s see how these choices play out in everyday products—from patio furniture to automotive parts—and what that means for their longevity and maintenance.

When you invest in new patio furniture, fencing, or even a flashy piece of jewelry, you want to know it will last. You might wonder: does aluminum patio furniture rust? What about that sleek aluminum fence or the aluminum trim on your car? Let’s walk through how aluminum performs in these everyday products, why it’s a favorite for so many uses, and what you should expect over the years.

Imagine leaving your patio set outside all summer—and through the rainy season, too. With steel or iron, you’d likely see orange-brown rust spots in no time. But with aluminum, things are different. Aluminum patio furniture is considered rust-proof, thanks to its natural oxide layer. This protective skin forms instantly and keeps moisture and oxygen from causing structural damage (Hauser's Patio).

However, because aluminum is lightweight, it can blow over in strong winds. And on hot days, the metal may feel warm to the touch—so cushions are a good idea for comfort.

Wondering, does aluminum fence rust? The answer is a resounding no. Aluminum’s resistance to corrosion makes it ideal for fencing, especially in humid or salty environments where other metals quickly deteriorate.

In short, aluminum fencing offers a long-lasting, rust-free solution for property boundaries and decorative railings.

In summary, whether you’re relaxing on your patio, securing your yard, or driving down the road, aluminum delivers a rust-free experience with minimal upkeep. Next, we’ll compare how aluminum and steel stack up in terms of corrosion—so you can make the most informed choice for your next project.

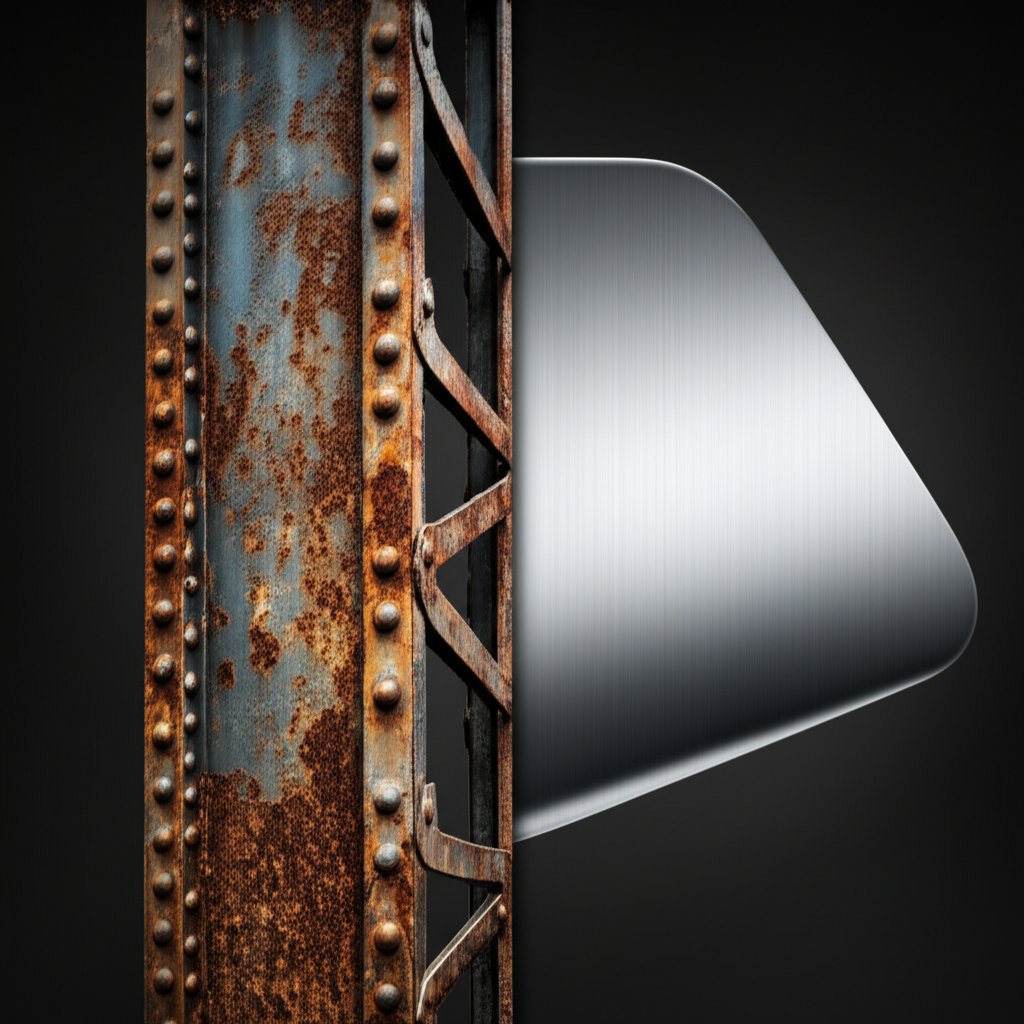

When you’re choosing between aluminum and steel for your next project, you might ask: does aluminum or steel rust faster? The answer can influence not only your material selection but also your long-term maintenance costs and the lifespan of your finished product. Let’s break down how these two metals behave when exposed to the elements and why their differences matter for real-world applications.

First, let’s clarify the terms. Rust is a specific type of corrosion that affects iron and steel, resulting in the familiar reddish-brown flakes (iron oxide) that can weaken and eventually destroy the metal. Oxidation is a broader term: it describes what happens when metals react with oxygen, but the outcome depends on the metal’s chemistry.

| Property | Aluminum | Steel (Carbon) |

|---|---|---|

| Corrosion Product | Aluminum oxide (hard, clear, protective) | Iron oxide (rust; flaky, porous, destructive) |

| Protective Layer | Forms instantly, self-healing, tightly bonded | Porous; flakes off, exposes more metal |

| Appearance Over Time | Dull gray or white patina; rarely structural damage | Reddish-brown rust, pitting, eventual structural failure |

| Need for Coatings | Usually not required (except in harsh conditions) | Often needed (paint, galvanizing, etc.) for protection |

| Corrosion Rate | Very slow in most environments | Rapid unless protected, especially outdoors |

| Longevity/Maintenance | Minimal upkeep, long service life | Regular maintenance required to prevent rust |

So, does aluminum rust faster than steel? In almost all typical environments, steel rusts significantly faster than aluminum corrodes. Here’s why:

In fact, aluminum is widely recognized as one of the most rust-resistant metals used in construction and manufacturing, while plain carbon steel is known for its tendency to rust unless protected.

"Aluminum offers better corrosion resistance than steel. When aluminum oxidizes, the aluminum oxide remains on the metal, protecting it against further corrosion. Steel, by contrast, needs coatings to prevent rust and will otherwise deteriorate quickly when exposed to the elements."

Ultimately, understanding how aluminum and steel react to their environments ensures you choose the right material for durability, maintenance, and performance. Next, we’ll clear up some common misconceptions and offer practical tips for keeping your aluminum in top condition.

When you see a white or dull film on an aluminum surface, you might wonder: does aluminum ever rust? It’s a common question, especially if you’re used to seeing rusty patches on steel or iron. The answer, as we’ve explored throughout this guide, is clear—aluminum does not rust in the traditional sense. Instead, it undergoes a unique process called oxidation, which forms a protective aluminum oxide layer rather than the flaky, destructive rust seen on iron-based metal.

So, while you might see changes in color or texture, what you’re witnessing is not rust, but a natural defense mechanism that keeps aluminum strong and intact for years.

Although aluminum is highly resistant to corrosion, it’s not completely invincible. In certain conditions—such as exposure to chloride ions (salt), acidic or alkaline environments, or when in contact with dissimilar metals—aluminum’s protective oxide layer can be compromised. This may lead to localized corrosion like pitting, but even then, the process is typically much slower and less destructive than rust on steel.

Want to keep your aluminum surfaces looking like new? Here are some easy, effective steps for aluminum corrosion prevention:

By following these simple guidelines, you’ll extend the life and appearance of your aluminum products, whether they’re patio furniture, railings, or building components.

In summary, while aluminum never truly rusts, understanding its unique oxidation process and taking proactive steps for corrosion prevention ensures your investment remains attractive and functional for years to come. Up next, we’ll recap the essential advantages of aluminum and how to make the most of its natural corrosion resistance in your next project.

After exploring the question “does aluminum rust?” from every angle, you now know that aluminum stands apart from iron and steel in the world of metals. While rust is the sworn enemy of iron-based materials, aluminum’s unique chemistry grants it a natural shield—its self-healing oxide layer. This means that, in most environments, you’ll enjoy the benefits of aluminum corrosion resistance for years with minimal maintenance.

When planning your next construction, industrial, or design project, selecting high quality aluminum profiles is crucial for achieving the best results. Leading manufacturers like Shengxin Aluminum combine advanced production capabilities with deep expertise in alloy selection, extrusion, and surface treatment. Their commitment to quality and innovation ensures that every profile is engineered for maximum longevity, reliability, and visual appeal.

So, whether you’re building for durability, aesthetics, or both, aluminum’s natural corrosion resistance makes it a smart and sustainable choice. Explore the possibilities with trusted experts and discover how the right aluminum profiles can elevate your next project—delivering strength, beauty, and peace of mind for years to come.

No, aluminum does not rust as iron or steel does. Rust specifically refers to iron oxide, which forms on iron-based metals. Aluminum forms a thin, protective oxide layer when exposed to oxygen, which shields it from further corrosion and prevents the flaky, reddish-brown rust seen on steel.

Aluminum is highly resistant to corrosion in water and outdoor environments due to its self-healing oxide layer. In pure water or moderate humidity, this layer remains stable. However, in the presence of salts, acids, or alkaline substances, the protective barrier can be compromised, leading to localized corrosion such as pitting, especially in coastal or polluted areas.

Saltwater and coastal air contain chloride ions that can penetrate aluminum's oxide layer, causing pitting corrosion. While aluminum won't rust, it can develop small pits that may affect structural integrity over time. Using marine-grade alloys, anodizing, or powder coatings helps protect aluminum in these harsh environments.

The corrosion resistance of aluminum depends on its alloy composition and surface treatment. Alloys with magnesium (like 5xxx series) offer enhanced resistance, while those with copper are more prone to corrosion. Anodized aluminum has a thickened oxide layer, providing superior protection. Cast aluminum can be more vulnerable due to porosity and alloying elements.

To prevent aluminum corrosion, regularly clean surfaces to remove contaminants, avoid harsh chemicals, and apply protective coatings such as anodizing or powder coating for added durability. In marine or industrial settings, choose appropriate alloys and minimize contact with dissimilar metals to reduce the risk of galvanic corrosion.

บริการออนไลน์

บริการออนไลน์ 0086 136 3563 2360

0086 136 3563 2360 sales@sxalu.com

sales@sxalu.com +86 136 3563 2360

+86 136 3563 2360