Ever wondered why aluminum is the go-to material for everything from airplanes to beverage cans? The answer often comes down to one essential property: density. But what exactly does "density of aluminum kg/m3" mean, and why does it matter so much?

Density, at its simplest, is the amount of mass packed into a given volume—think of it as how heavy something feels for its size. In technical terms, it's measured in kilograms per cubic meter (kg/m³). For engineers and designers, knowing a material's density is like having a secret formula for success. It helps them predict weight, design safer structures, and fine-tune performance across a wide range of industries.

But the story doesn’t end with pure aluminum. The "aluminum density in kg m3" can vary depending on the specific alloy and its intended use. Manufacturers often tweak the composition to achieve the perfect mix of properties for each application, which means understanding density isn’t just about memorizing a number—it’s about knowing how to apply it in real-world scenarios.

In this guide, you'll discover:

Ready to unlock the full potential of aluminum? Let’s start by answering the core question: what is the density of aluminum in kg/m³, and why is it the industry benchmark?

When you pick up a piece of aluminum and wonder, “Why does this feel so light compared to other metals?”—you’re really asking about its density. So, what is the standard aluminum kg/m3 value that engineers and manufacturers use every day?

The pure aluminum density is approximately 2,700 kilograms per cubic meter (kg/m³). In simple terms, this means that if you had a solid block of aluminum measuring exactly one cubic meter, it would weigh about 2,700 kilograms. This value is consistent under standard room temperature conditions and is widely accepted across engineering, scientific, and industrial communities. You’ll see it referenced in technical documents, material charts, and even in everyday calculations for construction, manufacturing, and transportation. For reference, please check this blog post.

It’s important to note that this value—2,700 kg/m³—applies specifically to pure or commercially pure aluminum. However, in practice, most aluminum used in real-world applications is alloyed with small amounts of other elements to enhance properties like strength or corrosion resistance. These additions may shift the density slightly, but the standard value remains a trusted starting point for most calculations.

Now that you know the accepted figure for pure aluminum, let’s explore why this number is so widely used in engineering and how it was established as the industry standard.

Imagine you’re designing a lightweight bridge or calculating how much an airplane part will weigh. You need a number you can trust—a value that’s recognized around the world. That’s where the standard density of aluminum comes in: 2,700 kg/m³ is the universally accepted figure for pure or commercially pure aluminum.

This number isn’t just a rough estimate. It’s based on precise laboratory measurements using high-purity aluminum at a standard temperature of 20°C. Why 20°C? That’s the reference point most scientists and engineers use for consistency, since temperature can slightly affect density due to thermal expansion. The value of 2,700 kg/m³ is supported by leading technical references and industry organizations, and it lines up with the SI (International System of Units) standards for material properties.

Using the density of aluminum 2700 kg/m3 simplifies calculations for mass, volume, and weight in everything from building plans to product design. It’s the go-to number for engineers, architects, and manufacturers because it:

While real-world aluminum may include minor impurities or alloying elements, this standard value offers a practical, trusted foundation for science and industry. Next, let’s see how alloying elements can shift this number—and what that means for specialized applications.

When you hear “aluminum,” you might picture a shiny soda can or a sturdy window frame. But did you know that not all aluminum is created equal? In fact, the density of aluminum alloys can shift depending on which elements are blended into the mix. Sounds complex? Let’s break it down so you can see why these variations matter for everything from skyscrapers to car frames.

Pure aluminum is rarely used alone in demanding applications. To boost its strength, durability, or corrosion resistance, manufacturers add small amounts of other metals—creating what’s known as an aluminum alloy. This process is like customizing a recipe: each added ingredient changes the final product’s properties, including its density.

Imagine you’re adjusting a recipe by adding new ingredients. Each addition changes not just the flavor, but also the weight and texture. Similarly, when elements like copper, magnesium, silicon, or zinc are introduced to aluminum, they alter both its mechanical properties and its density.

For example, while the density of pure aluminum is standardized at 2,700 kg/m³, certain high-strength alloys can approach or exceed 2,900 kg/m³. Others, like some 4xxx series, may have densities slightly below the baseline. Even these small changes can dramatically influence the final weight and performance of a component.

Leading manufacturers like Shengxin Aluminum play a pivotal role in this process. By carefully selecting alloying elements and controlling production conditions, they can engineer aluminum alloys with densities and strengths tailored for specific projects—whether it’s lightweight frames for electric vehicles or robust profiles for architectural facades. Their advanced extrusion and finishing technologies ensure each batch meets strict quality standards, giving engineers and architects confidence in their material choices.

So, the next time you see an aluminum window frame or a bicycle made from a specific alloy, remember: its density wasn’t chosen at random. It’s the result of careful engineering, balancing weight, strength, and performance for the demands of modern design. In the next section, we’ll zoom in on one of the most popular alloys—6061 aluminum—and see how its unique composition influences its density and everyday uses.

Ever wondered why 6061 aluminum is everywhere—from bicycle frames to aircraft fittings? One key reason is its balanced combination of strength, workability, and, of course, its density. But what is the density of 6061 T6 aluminum kg m3, and why does it matter for engineers and designers?

The 6061 aluminum density is typically 2,720 kg/m³ (source). This value is just slightly higher than pure aluminum’s standard 2,700 kg/m³. Why the difference? The answer lies in the alloying elements—mainly magnesium and silicon—that are added to create the 6061 alloy. These elements make the alloy stronger and more versatile, but they also add a small amount of mass per unit volume, nudging the density upward.

This slight increase may seem minor, but when you’re calculating the mass of large structures or components, even small differences in density can add up.

Imagine you’re designing a lightweight bike frame or a structural support for a building. If you use the wrong density in your calculations, your weight estimates could be off—potentially leading to design flaws or safety issues. That’s why manufacturers and engineers rely on precise values for each alloy.

In summary, the density of 6061 T6 aluminum kg m3 is a cornerstone property, helping engineers achieve the right balance of weight and strength for a wide range of applications. Next, let’s see how other high-strength alloys like 2024 and 7075 compare in terms of density and typical uses.

When you’re selecting materials for an aircraft wing or a racing bicycle, you’ll notice that not all aluminum alloys are created equal. Two of the most prominent high-strength alloys—2024 and 7075—stand out for their unique blend of properties. But how do their densities compare, and why does it matter for your next engineering project?

Both 2024 and 7075 are renowned in the aerospace and high-performance manufacturing sectors. Their strength-to-weight ratios make them ideal for applications where every gram counts and reliability is non-negotiable. But as you’ll see, subtle differences in their densities can have a big impact on performance and design choices.

Let’s break down the differences among some of the most commonly used aluminum alloys. The table below highlights each alloy’s primary elements, typical density, and where you’re most likely to encounter them in the real world:

| Alloy Designation | Primary Alloying Elements | Typical Density (kg/m³) | Common Applications |

|---|---|---|---|

| Pure Aluminum | None (99%+ Al) | 2,700 | Electrical conductors, packaging, chemical equipment |

| 6061 | Magnesium, Silicon | 2,720 | Bicycle frames, structural extrusions, automotive parts |

| 2024 | Copper | ~2,780 | Aerospace structures, rivets, truck wheels |

| 7075 | Zinc, Magnesium | ~2,810 | Aerospace components, high-stress parts, sports equipment |

As the table shows, the density of 2024 aluminum is typically around 2,780 kg/m³, while the density of 7075 aluminum rises to about 2,810 kg/m³. These increases are a direct result of their alloying elements—copper for 2024 and zinc/magnesium for 7075—which not only boost strength but also add to the overall mass per unit volume.

Imagine you’re building a lightweight aircraft part. Even a small increase in density can add up when multiplied across hundreds of components. Choosing the right alloy means balancing the need for maximum strength with the lowest possible weight. For example:

Understanding these subtle differences allows engineers to make informed decisions—ensuring every part meets performance, safety, and weight targets. Next, let’s explore the physical factors beyond alloy composition that can influence aluminum’s density in real-world scenarios.

When you picture a block of aluminum, you might assume its density is always the same. But is it? In reality, several physical factors can subtly shift how tightly aluminum’s atoms are packed together. Let’s break down the main influences—temperature, pressure, and physical state—so you can see why the aluminum density temperature and aluminum density pressure relationship matters for real-world projects.

Imagine leaving an aluminum rod out in the sun. As it heats up, what happens? Like most materials, aluminum expands when warmed. This expansion means the same mass now occupies a slightly larger volume—so the density drops. Conversely, cooling aluminum causes it to contract, squeezing the atoms closer together and increasing density. For most day-to-day applications, these changes are minor, but in high-precision engineering or extreme environments, even small shifts can impact performance.

Now, think about aluminum deep underground or in specialized industrial presses. As pressure rises, the metal compresses, reducing its volume and increasing its density. While this effect is minimal at everyday pressures, it becomes significant in high-pressure research or geophysical studies. For example, researchers have measured the structure and density of liquid aluminum at pressures up to 6.9 GPa (gigapascals), noting that increased pressure can noticeably compact the material (source).

Ever wondered what happens to density when aluminum melts? When aluminum transitions from solid to liquid, its atoms move further apart, causing a drop in density. For instance, pure aluminum’s density is about 2,699 kg/m³ in solid form, but drops to around 2,357 kg/m³ when liquid at 973 K. This shift is crucial for casting and manufacturing processes, where precise volume calculations are needed for molten metal.

Understanding these factors ensures you can accurately predict aluminum’s behavior—whether you’re building a satellite, designing a pressure vessel, or casting engine parts. Next, let’s see how aluminum’s density compares to other common metals, so you can make the smartest material choice for your next project.

When choosing the right material for your project, have you ever wondered why aluminum is so often picked over other metals? The answer often comes down to one key property: density. Let’s break down a density of metals comparison to see where aluminum stands—and why it’s such a game-changer for lightweight design.

Imagine you’re designing a car, an airplane, or even a laptop case. The weight of the material you choose impacts everything from fuel efficiency to ease of handling. Aluminum’s primary advantage is its low density, which means you get the same volume for much less weight compared to heavier metals like steel or copper.

| Metal | Typical Density (kg/m³) | Relative Weight (to Aluminum) | Common Applications |

|---|---|---|---|

| Aluminum | 2,712 | 1.0 | Aircraft, automotive parts, packaging, construction |

| Magnesium | 1,740 | 0.64 | Automotive, aerospace, electronics casings |

| Titanium | 4,500 | 1.66 | Aerospace, medical implants, sports equipment |

| Steel | 7,860 | 2.9 | Construction, automotive frames, machinery |

| Copper | 8,940 | 3.3 | Electrical wiring, plumbing, heat exchangers |

So, next time you see a sleek aircraft wing or a lightweight car hood, you’ll know: aluminum’s low density is at the heart of modern engineering innovation. In the following section, you’ll learn how to use these density values for practical mass calculations—so you can make the smartest choice for your next project.

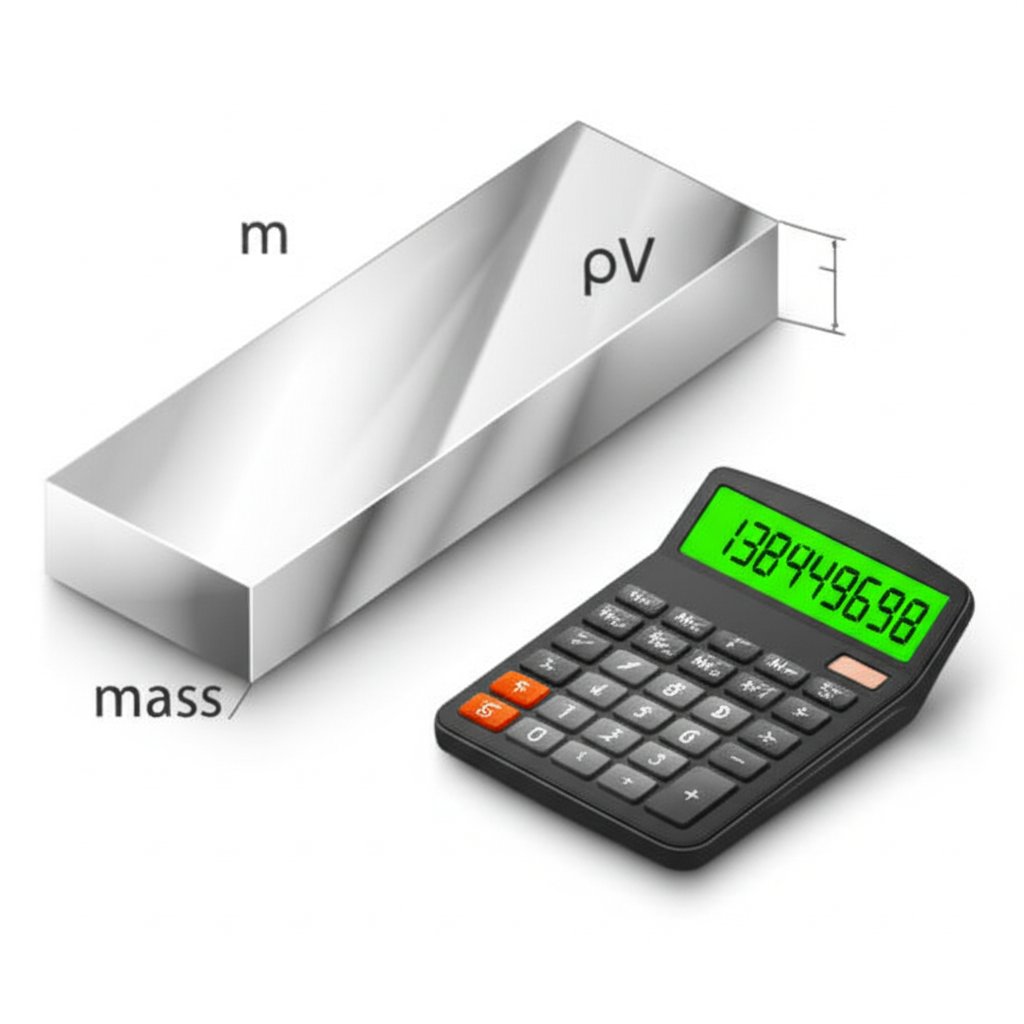

Ever faced a project where you needed to know exactly how much your aluminum component would weigh? Whether you’re building a custom machine part, designing a lightweight structure, or budgeting for transport costs, accurate aluminum weight calculation is crucial. But how do you go from density data to a real-world mass you can trust?

Let’s start with the basics. The mass of any object can be found using this straightforward equation:

Mass = Density × Volume

Here’s what each term means:

Imagine you need to calculate mass from density for a solid rectangular aluminum bar. Here’s how you’d do it:

So, your aluminum bar would weigh 27 kilograms.

While the math is simple, the real challenge is choosing the correct density value for your alloy and application. Small differences can add up, especially in large-scale or high-precision projects. That’s why engineers often rely on manufacturer specifications and advanced extrusion capabilities—like those offered by Shengxin Aluminum—to ensure every part meets strict performance and weight criteria. Custom profiles, intricate shapes, and specific alloy blends all require precise density data for accurate calculations and product consistency.

In summary, mastering aluminum weight calculation empowers you to design smarter, budget accurately, and deliver results that meet both safety and performance standards. Up next, we’ll wrap up with key takeaways and how this knowledge helps you make better material choices for your next project.

When you step back and look at the big picture, understanding the density of aluminum kg/m3 is more than just a technical detail—it's a strategic advantage in modern engineering and design. Imagine planning a new structure, optimizing a vehicle for efficiency, or selecting the right material for a high-performance component. Wouldn’t you want every calculation to be as accurate as possible?

But why stop at theory? Every successful project hinges on applying these principles to real-world challenges—whether you’re calculating the load for a bridge or specifying lightweight profiles for advanced machinery. When you use this aluminum density guide, you’re equipped to make informed material choices that drive innovation and efficiency.

For those seeking custom solutions or large-scale production, partnering with an expert aluminum profile manufacturer can make all the difference. Companies like Shengxin Aluminum combine deep technical expertise with advanced manufacturing capabilities, delivering profiles that meet the strictest specifications for weight, strength, and performance. Their commitment to quality and customization ensures your next project benefits from the full potential of aluminum’s unique properties.

Ready to put your knowledge to work? Let this guide be your starting point for smarter, data-driven decisions—and don’t hesitate to explore tailored solutions from leading manufacturers when precision and performance truly matter.

The standard density of pure aluminum is 2,700 kg/m³. This value is widely recognized in engineering and is used as the baseline for most calculations involving aluminum materials.

Alloying aluminum with elements like magnesium, silicon, copper, or zinc can slightly increase or decrease its density, depending on the alloy blend. These changes are important for optimizing strength, weight, and performance in specific applications.

Aluminum's relatively low density allows for lighter, more fuel-efficient designs without sacrificing strength. This makes it a top choice in aerospace, automotive, and construction, where weight savings can lead to significant performance and cost benefits.

To calculate mass, multiply the density of the specific aluminum alloy (in kg/m³) by the object's volume (in m³). For example, mass = density × volume. Using the correct density ensures accurate weight estimates for engineering and manufacturing.

Shengxin Aluminum provides advanced extrusion, alloy customization, and precise manufacturing capabilities, ensuring each aluminum profile meets strict specifications for density, strength, and performance in large-scale or specialized projects.

บริการออนไลน์

บริการออนไลน์ 0086 136 3563 2360

0086 136 3563 2360 sales@sxalu.com

sales@sxalu.com +86 136 3563 2360

+86 136 3563 2360