Imagine you’re stepping into a building—what keeps the wind, water, and dirt outside, while giving your entry a finished look? That’s the job of the door threshold. In 2025, thresholds for doors are more than just a finishing strip. They serve as the essential barrier at the bottom of the door opening, blocking drafts, channeling water, and creating a smooth transition between floor surfaces. Whether for homes or commercial spaces, the right aluminum threshold can make a noticeable difference in energy efficiency, comfort, and code compliance.

Ever wondered about the difference between a door sill vs threshold, or what is a door saddle? These terms are often used interchangeably, but they each have specific meanings in door construction. Here’s a quick comparison to clarify:

| Term | Definition | Placement in Assembly |

|---|---|---|

| Threshold | The horizontal strip at the base of a door, bridging the gap between the door and floor, sealing out weather and debris. | Bottom of door opening, above sill pan or subfloor |

| Sill | The structural element beneath the threshold, supporting the door frame and sometimes integrating water drainage features. | Lowest part of door frame, in contact with subfloor |

| Saddle | A threshold profile with a raised center (like a saddle), designed for water deflection and smooth transitions between different floor heights. | Above sill, between interior and exterior flooring |

| Sweep | Flexible strip attached to the bottom of the door, working with the threshold to enhance sealing against drafts and water. | Bottom edge of door leaf, contacts threshold |

Why choose an aluminum threshold over wood or vinyl? The answer lies in its unique blend of durability, corrosion resistance, and dimensional stability. Aluminum doesn’t rot, warp, or swell—making it ideal for high-moisture or high-traffic areas. You’ll notice that modern door thresholds made from aluminum are lighter and easier to install, yet tough enough to withstand years of foot traffic and exposure to the elements. This makes them a preferred solution for both exterior and interior applications, especially where long-term performance is critical.

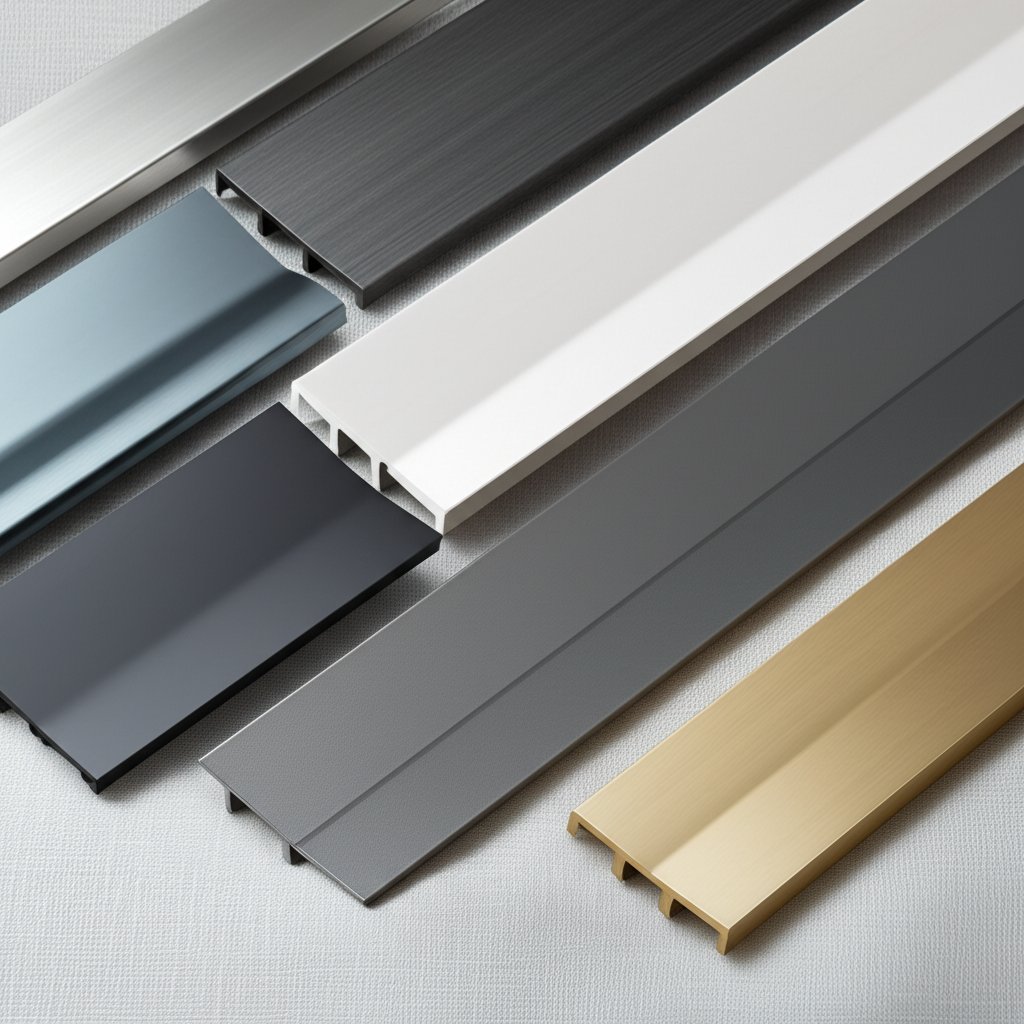

Common aluminum threshold forms include:

Key Takeaway: The right slope, integrated weep channels, and optional thermal breaks in an aluminum threshold are crucial for managing water, controlling drafts, and meeting energy codes. Always match threshold height and slope to the final floor finish and code requirements to ensure accessibility and weather protection.

Aluminum thresholds sit at the interface of the door leaf and the floor, working together with weatherstripping and sill pans to create a comprehensive barrier. When selecting a threshold for door installations, it’s essential to consider not only the material but also the profile, slope, and how it interacts with the rest of the door assembly.

In summary, understanding the distinctions between threshold, sill, and saddle—and knowing why aluminum is often the best choice—sets the foundation for selecting, sizing, and installing thresholds that meet the demands of modern buildings. As you move through this guide, you’ll see how these basics connect directly to code compliance, measurement, and long-term performance.

When you’re choosing an aluminum door threshold or aluminum door saddle, the material and finish can make or break its long-term performance. Sounds complex? Let’s break it down. Most thresholds are made from extruded aluminum, typically using alloys like 6063-T5 for standard applications or 6061-T6 when extra strength is needed. These alloys strike a balance between machinability, corrosion resistance, and the ability to take on various finishes. The extrusion process is governed by standards such as ASTM B221, ensuring consistent quality and dimensional accuracy.

Finish options matter just as much as alloy. You’ll see thresholds in mill finish (bare aluminum), clear or bronze anodized, and powder-coated colors. Anodizing not only adds color but also forms a protective oxide layer—typically 0.4–0.7 mil thick (AA-M10 spec)—making the surface harder and more resistant to scratches and corrosion. Powder coating offers a thicker, more uniform color layer and is popular for matching interior design or branding. The right finish means your metal door threshold stays looking sharp and is easier to clean.

Imagine you’re comparing materials for a high-traffic entry or a coastal property. The choice isn’t just about looks—it’s about cost, durability, and how much upkeep you want. Here’s a side-by-side comparison to help you decide:

| Material | Pros | Cons | Approx. Cost/ft (2025 USD) | Expected Service Life | Maintenance Level | Best Use Scenarios |

|---|---|---|---|---|---|---|

| Aluminum |

|

|

$4–$8 | 10–20 years | Low (anodized/powder coat), Moderate (mill finish) | Residential & commercial, interior/exterior, adjustable or saddle profiles |

| Bronze/Brass |

|

|

$12–$20 | 20–30 years | Moderate (occasional polishing) | Historic renovations, luxury entries, brass door threshold look |

| Stainless Steel |

|

|

$15–$30 | 25–40 years | Low | Industrial, commercial, marine, stainless steel door threshold |

| Composite/Vinyl |

|

|

$3–$6 | 8–12 years | Low | Interior, low-traffic, energy-efficient builds |

Ever noticed how some thresholds lose their luster or start to show scratches after a few years? That’s often about finish choice. Anodized and powder-coated metal door thresholds offer the best protection against wear, especially in high-traffic commercial spaces. For interior doors, a prefinished metal door sill or even a mill finish might suffice, but exterior doors benefit from tougher finishes that stand up to weather and cleaning chemicals.

Pro Tip: For high-traffic commercial entries, choose anodized or powder-coated aluminum thresholds to minimize cleaning intervals and preserve appearance. These finishes resist abrasion and are less likely to show wear compared to mill finish or composite options.

Placement matters too. Exterior thresholds face more moisture and dirt, so opt for finishes that can handle regular cleaning and resist corrosion. For interior transitions, especially where aesthetics matter, a brass door threshold or aluminium door saddle can provide a decorative touch with less maintenance.

Bottom line: Selecting the right material and finish for your threshold isn’t just about today’s look—it’s about years of reliable service and minimal headaches. Up next, we’ll dive into how codes and performance standards shape your selection so you avoid costly mistakes down the road.

When you’re selecting an aluminum threshold for your project, code compliance isn’t optional—it’s essential. Sounds complex? Let’s break it down. The 2010 ADA Standards specify that any ada threshold in new construction must not exceed 1/2 inch in height, and anything above 1/4 inch must have a beveled edge with a maximum slope of 1:2. For transitions, the slope should not be steeper than 1:48—a critical detail for wheelchair access and trip prevention. This applies to all types of ada door threshold installations, including sliding doors and vestibules (ADA Guide).

| Threshold Type | Max Vertical Height (inches) | Bevel/Slope Requirement | ADA Compliant? |

|---|---|---|---|

| Flat/Low-Profile | 1/4 | None required | Yes |

| Beveled | 1/2 | 1:2 bevel (above 1/4 in) | Yes |

| Full Saddle (w/ ramp) | 1/2 | 1:2 bevel, slope ≤1:48 | Yes |

| Legacy/Existing | 3/4 | 1:2 bevel both sides | Alteration Only |

Code Reminder: For any ada compliant door threshold, keep vertical height ≤1/2 inch with a 1:2 bevel above 1/4 inch, and ensure ramps or transitions maintain a slope ≤1:48 for smooth, safe access.

Ignoring these requirements can lead to failed inspections, costly rework, or—worse—accessibility complaints. Always check the exterior door threshold detail and final floor build-up before ordering, as improper layering can push you over the allowed height.

How do you know if your threshold exterior will keep out drafts and water? That’s where performance testing comes in. Industry standards such as ASTM E283 (for air leakage) and ASTM E331 (for water penetration) are used to validate exterior door threshold detail and weather resistance. In these tests, lower air leakage (cfm/ft² at 1.57 psf) and lower water infiltration rates (gph/sqft) mean better performance.

Some designs, like interlocking door threshold profiles, provide enhanced sealing by mechanically connecting with the door bottom or sweep. This is especially valuable for high-exposure entries or where wind-driven rain is a concern. For a visual reference, review an exterior door threshold diagram to see how these elements work together with weatherstripping and sill pans.

Imagine a cold winter morning—if your aluminum threshold has no thermal break, it could act as a bridge for heat loss. Thermally broken profiles insert a non-conductive barrier between interior and exterior aluminum, dramatically reducing heat transfer. This not only helps meet energy codes but also prevents condensation and ice buildup at the threshold. In cold climates or energy-efficient projects, always specify a thermally broken threshold for optimal performance.

Low-profile aluminum thresholds are often the best fit for ADA compliance, but don’t sacrifice weather resistance. Always balance height, slope, and sealing features to meet both code and performance needs.

By understanding these codes and metrics, you’ll confidently select the right aluminum threshold—one that passes inspection, stands up to the elements, and supports accessibility. Next, we’ll walk through measurement and ordering, so you get the perfect fit every time.

When it comes to ordering the right aluminum threshold, accuracy is everything. Sounds complex? Not if you follow a proven workflow. An ill-fitting threshold can lead to drafts, water leaks, or even damage to your door. Here’s how to get it right the first time—whether you’re replacing an old strip or installing a new wide door threshold for a remodel.

Field Tip: If your jambs are out of square, order the threshold 1/2 inch longer than measured and trim to fit on site for a custom, gap-free installation.

Let’s make it practical. Here are four real-world examples you can mirror for your own project, whether you need a sliding door threshold, a 32 inch door threshold, or something custom for a commercial entry.

| Door Size & Application | Recommended Profile | Finish | Fastener Pattern | Cut Length |

|---|---|---|---|---|

| 36" Exterior, tile porch, needs ramp | Thermal-break, 1" ramped | Bronze anodized | 8" OC, pre-drilled | 36.5" (for field trim) |

| 32" Interior, carpet-to-tile | Low-profile half saddle | Clear anodized | 10" OC, pre-drilled | 32.5" |

| 72" Double door vestibule | Adjustable saddle, wide door threshold | Mill finish | 6" OC, pre-drilled | 72.5" |

| 74" Sliding patio, with weep management | Flat profile with integrated weep holes | Powder coat, custom color | 8" OC, field drill | 74.5" |

Ready to order? Use a part code template to get exactly what you need and avoid confusion:

AL-THR-[TYPE]-[WIDTH]-[FINISH]-[TB]-[DRIP]

For example, a 74-inch powder-coated sliding door threshold with thermal break and weep holes might be:

AL-THR-flat-74-powdercoat-yes-weep

By following these steps and using the ordering template, you’ll ensure your aluminum threshold fits perfectly, performs as expected, and meets all code and transition needs. Next, we’ll dive into installation tips to guarantee your new threshold stands the test of time.

When you’re ready for an exterior door threshold replacement, a smooth installation is the key to zero re-work and lasting performance. Whether you’re tackling a front door threshold replacement, upgrading commercial metal door sills, or installing a new threshold for a sliding patio, following the right steps ensures your threshold plate delivers reliable weather resistance and code compliance.

Quality Checklist:

- Threshold slopes outward for drainage

- Continuous sealant bead under and at ends

- No gaps at jambs or under threshold

- Weep holes clear and facing exterior

- Door sweep compresses evenly on threshold plate

- No visible movement or flex when walked on

| Threshold Type | Recommended Screw Spacing | Notes |

|---|---|---|

| Commercial Saddle | 6–8 in on center | Stainless screws preferred; check for fire rating |

| Residential Adjustable | 8–10 in on center | Do not overtighten adjustment screws |

| Flat/Low-Profile | 8–10 in on center | Shim any low spots before fastening |

Common mistakes to avoid: Failing to shim under high spots, not sealing metal threshold plate ends, or overtightening screws can lead to leaks, warping, or a loose fit. For fire-rated assemblies, always defer to certified professionals for installation.

By following these step-by-step instructions, your replacement door threshold will deliver years of reliable service, withstanding weather, foot traffic, and inspection scrutiny. Up next, we’ll cover maintenance and troubleshooting tips to keep your threshold performing like new.

When you want your aluminum threshold to last for years without surprise repairs, a simple maintenance routine is your secret weapon. But what does that really look like? Imagine you’re creating a checklist for your home or business—here’s a practical breakdown:

| Task | Interval | Materials | Pass/Fail Criteria |

|---|---|---|---|

| Clean threshold strip (all finishes) | Quarterly | pH-neutral detergent, soft cloth/brush | No visible dirt, stains, or chalky build-up |

| Inspect and re-seal joints/ends | Biannually | Silicone sealant | No cracks, gaps, or dried-out sealant |

| Check and re-torque fasteners | Annually | Screwdriver, torque wrench | No loose screws; threshold firmly anchored |

| Replace weather strip for threshold | Annually or as needed | Rubber threshold strip, replacement parts | Even compression, no tears or gaps |

| Polish anodized/powder-coated finishes | Semi-annually | Non-abrasive polish (if needed) | Consistent shine, no surface haze |

Wondering how to clean aluminum door threshold surfaces without causing damage? Stick to mild, pH-neutral cleaners and a soft cloth or brush. Avoid abrasive pads and harsh chemicals, especially near coastal areas, as chloride-based agents can accelerate corrosion. For stubborn stains, a vinegar-water mix or a specialized aluminum cleaner works well. Finish with a protective polish if your threshold has an anodized or powder-coated finish.

Even with the best care, issues can pop up. Here’s a troubleshooting list to map common symptoms to likely causes and quick fixes—so you can solve problems before they become costly repairs:

Important: Always seal cut ends of the threshold and any fastener penetrations with silicone or appropriate sealant. This prevents galvanic corrosion and extends the life of your replacement threshold, especially in damp or coastal environments.

Not sure if you need a full aluminum threshold replacement or just a quick fix? Here’s how to decide:

Expect to spend 30–60 minutes on routine cleaning and re-torque/inspection. Swapping out new rubber inserts or weather strips typically costs $30–$60 and can be done in under an hour. A full aluminum threshold replacement may take 2–4 hours, especially if you need to trim the new strip or address subfloor repairs.

Remember, a little regular attention goes a long way. By following this maintenance plan and troubleshooting guide, you’ll extend the life of your aluminum threshold and avoid the headaches of premature failure. Up next, see how real-world case studies prove the value of these best practices in action.

Ever wondered if all the careful planning, code checks, and precise installation actually pay off in the real world? Let’s look at three practical case studies—covering residential, commercial, and healthcare settings—that show how the right aluminum threshold selection and installation can deliver measurable improvements in comfort, safety, and durability.

Imagine a 1960s home with drafty, outdated front door thresholds. The homeowner opted for a thermally broken half saddle aluminum threshold with a 0.5-inch beveled height. This upgrade was chosen for its energy-saving properties and smooth door threshold transition. After installation, the homeowner reported a 15–20% reduction in drafts and no water ingress—even after a 2-inch-per-hour rainfall. The improvement wasn’t just about comfort; it also meant fewer maintenance calls and lower energy bills. This case highlights how even a single exterior door saddle replacement can have a big impact when you match the profile and finish to the door’s exposure and use.

In a busy retail environment, the original commercial door threshold was prone to leaks and frequent replacement. The property manager decided on a commercial door threshold replacement using an adjustable saddle with a weeped sub-sill. The new system was selected for its robust load-bearing capacity and integrated water management—crucial for heavy foot traffic and exposure to the elements. Over the following 12 months, water infiltration events dropped from monthly to zero, and maintenance calls related to the threshold disappeared. This retrofit demonstrates that the right aluminum threshold can dramatically improve durability and reduce total cost of ownership in commercial spaces.

Hospitals require safe, accessible transitions for patients and staff. In this case, a healthcare facility upgraded several corridor entries to low-profile, ADA compliant threshold aluminum extrusions with a 1:48 bevel. The decision was driven by the need to reduce wheel resistance for carts and wheelchairs, while also preventing trip hazards. Post-installation, staff reported noticeably smoother movement across the thresholds, and incident reports for trips or stumbles at these locations dropped significantly. Additionally, the maintenance team noted less wear on cleaning equipment and fewer repairs needed over time—proving the value of a code-ready aluminum garage door threshold or corridor transition.

| Project | Before | After |

|---|---|---|

| Single-family entry |

Frequent drafts, water leaks High energy use |

15–20% draft reduction No water ingress Lower energy bills |

| Retail storefront |

Monthly water infiltration Frequent repairs |

Zero leaks in 12 months No threshold-related maintenance |

| Hospital corridor |

High wheel resistance Trip incidents Maintenance calls |

Smoother transitions Fewer trips and calls Improved accessibility |

Insight: In cold or wet climates, thermally broken aluminum thresholds are a game-changer—reducing drafts, preventing condensation, and maintaining comfort year-round.

The lessons from these projects are clear: matching the aluminum threshold profile, finish, and installation to your environment pays off in performance and longevity. Whether you’re planning a patio door threshold upgrade, a full commercial retrofit, or a hospital corridor transition, these results show that a thoughtful approach to selection and installation delivers code-ready, real-world benefits. Next, let’s explore how to source quality thresholds and compare suppliers for your next project.

When you’re ready to order aluminum thresholds for your project, the right supplier can make all the difference. But with so many options—custom extruders, regional distributors, and big-box retailers—how do you choose? Imagine you need a batch of commercial door thresholds for a busy storefront, or perhaps you’re after a few threshold parts for a residential remodel. The best supplier is the one who matches your specs, lead time, and quality expectations—without surprises or rework.

| Supplier | Customization | Finish Options | Thermal Breaks | Certifications | Lead Time | Price Tier | Best For |

|---|---|---|---|---|---|---|---|

|

Shengxin aluminum extrusion profiles China |

Full custom (profile, size, alloy) | Anodized, powder coat, wood grain | Yes | ISO, ASTM | 2–6 weeks (custom) | $$ | Large projects, spec-driven jobs, unique designs |

| Regional Distributors | Limited (stock profiles, cut-to-size) | Clear, bronze anodized, mill | Some | ASTM (varies) | 1–2 weeks | $$ | Standard commercial thresholds, quick turnaround |

|

Big-Box Retailers (e.g., aluminum strips Home Depot) |

Off-the-shelf only | Mill, limited anodized | No | None/Basic | Same-day | $ | DIY, small repairs, residential |

|

Specialty Catalogs (e.g., Sweets Construction) |

Broad selection, some custom | Varies (by mfr.) | Some | ASTM, LEED (varies) | 2–4 weeks | $$$ | Architectural, green building, high-spec |

Lead time and customization are often the deciding factors. For unique profiles, thermal-break requirements, or special finishes, a manufacturer like Shengxin stands out—they offer custom extrusions, a wide range of finishes, and can tailor aluminum thresholds to your exact needs. Regional distributors and specialty catalogs are great for standard aluminium thresholds or when you need commercial door thresholds in a hurry. For basic repairs or one-off projects, big-box stores such as those carrying aluminum strips Home Depot style are your fastest bet.

Pro Tip: Always align ADA bevel heights with your final floor build-up—especially when ordering commercial threshold profiles. This helps you avoid costly return cycles and ensures every installation passes inspection.

Choosing the right supplier for your aluminum door thresholds is about more than price—it’s about getting the right fit, finish, and features for your project. Whether you need fully custom commercial door thresholds, off-the-shelf metal thresholds, or just a few replacement threshold parts, a careful procurement process ensures your installation is code-ready and built to last. Next, we’ll wrap up with an action plan for finalizing your threshold specs and making the smartest sourcing decisions.

Ready to wrap up your aluminum threshold selection? Imagine you’re standing at your doorway—do you know exactly which threshold type, finish, and features will deliver the best results? Here’s a scannable action plan to help you lock in the right choice, whether you’re upgrading a single entry or specifying thresholds for a commercial build:

Wondering if a thermally broken adjustable threshold is right for your project? If you’re dealing with extreme temperature differences, energy codes, or want to eliminate condensation at entry points, these profiles are your best bet. Adjustable designs are also ideal when floor heights or slopes vary, ensuring a snug, code-ready fit for any door threshold exterior scenario. This flexibility is especially valuable for commercial and high-traffic entries.

Imagine you need custom extrusions or a large volume of aluminum exterior door threshold assemblies. For projects that demand precise alloy, temper, finish, or thermal-break features—and documentation for ASTM or ADA compliance—explore aluminum extrusion profiles China from Shengxin. As a professional aluminum profile manufacturer, Shengxin delivers specification-ready solutions, and you can request samples and test data before committing to a bulk order.

Key Takeaway: Measurement accuracy and careful substrate preparation are the foundations of a high-performance threshold installation. Don’t rush these steps—getting them right ensures every threshold fits perfectly, performs reliably, and passes inspection.

By following this action plan, you’ll confidently select the right threshold for any application—balancing code compliance, durability, and energy efficiency. For custom or high-volume projects, partnering with a trusted supplier like Shengxin ensures your door threshold cap and all related profiles meet the highest standards. Ready to take the next step? Reach out for samples, test data, and expert guidance to complete your project with zero re-work and total peace of mind.

A door threshold is the strip at the base of a door that seals out drafts and water. The sill is the structural support beneath the threshold, often with drainage features, while a saddle is a raised threshold profile designed for smooth transitions and water deflection. Choosing the right type ensures proper sealing, durability, and code compliance.

Aluminum thresholds offer superior durability, corrosion resistance, and dimensional stability compared to wood or vinyl. They are ideal for high-traffic and high-moisture areas, require less maintenance, and provide a reliable barrier against weather, making them a preferred option for both residential and commercial doors.

To comply with ADA standards, select a threshold no higher than 1/2 inch with a 1:2 bevel above 1/4 inch, and ensure transitions have a slope of 1:48 or less. Always check local codes, confirm the final floor build-up, and request product specifications or certifications from your supplier to avoid costly rework.

Maintain aluminum thresholds by cleaning quarterly with pH-neutral detergent, inspecting and resealing joints biannually, and checking fastener tightness annually. Replace worn weatherstrips as needed, and avoid abrasive cleaners to preserve anodized or powder-coated finishes. Regular care extends the life and performance of your threshold.

For custom profiles, finishes, and thermal-break options, consider manufacturers like Shengxin Aluminum, which offers specification-ready extrusions and compliance documentation. Regional distributors and big-box retailers are suitable for standard sizes and quick repairs, while custom suppliers are best for large or specialized projects.

บริการออนไลน์

บริการออนไลน์ 0086 136 3563 2360

0086 136 3563 2360 sales@sxalu.com

sales@sxalu.com +86 136 3563 2360

+86 136 3563 2360