Ever wonder what makes "two-aught" or 2/0 aluminum wire the workhorse for modern electrical projects? In the American Wire Gauge (AWG) system, 2/0 (read as "two-aught") is a heavy-gauge wire—thicker than 2 AWG and designed for serious power delivery. Unlike smaller wires, 2 0 aluminum wire is engineered to handle high current loads in residential, commercial, and light industrial settings. The "aluminum" part means the conductor is made from aluminum alloy, which is lighter and more cost-effective than copper, though slightly larger in diameter for the same ampacity.

2/0 aluminum building wire is a heavy-duty conductor—about 0.364 inches in diameter—used to safely deliver high current where copper is impractical or cost-prohibitive.

When you compare 2/0 aluminum to copper, you’ll notice aluminum is typically chosen for longer runs and large feeder circuits where weight and budget matter. For example, 2 0 awg aluminum wire is common in service entrance cables, main feeders to subpanels, and direct burial installations. While copper still leads in ampacity per cross-sectional area, aluminum’s lower density and cost make it a smart choice for large-scale or cost-sensitive projects. In 2025, code-compliant aluminum alloys (like 8000 series) and improved terminations have made 2/0 aluminum a reliable alternative to copper in most building applications.

Choosing the right 2/0 wire isn’t just about the conductor—it’s about the whole assembly. Here are the most common types you’ll see:

| Spec | Typical Range | Notes |

|---|---|---|

| Diameter (conductor) | ~0.364 in | Excludes insulation |

| Strand Count | 7–19 strands | Depends on flexibility/class |

| Common Insulations | XHHW-2, THHN/THWN-2, USE-2 | Wet/dry, direct burial options |

| Standard Voltage Rating | 600 V | Building wire applications |

Before you select a 2/0 aluminum cable, consider these essentials:

By understanding what 2/0 aluminum wire is, where it excels, and the key factors in selecting the right construction, you’re ready to make informed choices for safe, code-compliant projects in 2025 and beyond. Ready to dig deeper into ampacity and sizing? Let’s move on to the next section.

When you’re sizing 2/0 aluminum wire, the first question is always: how many amps is 2/0 aluminum good for? The answer depends on insulation type, installation method, and—most importantly—equipment termination ratings. The National Electrical Code (NEC) Table 310.16 (formerly 310.15(B)(16)) is your starting point for finding the base ampacity of 2/0 aluminum conductors under standard conditions (no more than three current-carrying conductors, 30°C/86°F ambient temperature).

| Insulation Type | 60°C Column | 75°C Column | 90°C Column | Notes (Real-World Limits) |

|---|---|---|---|---|

| XHHW-2 | 135A | 150A | 175A | Most terminations: 75°C (150A) |

| THHN/THWN-2 | 135A | 150A | 175A | Use 75°C (150A) unless marked otherwise |

| USE-2 cable | 135A | 150A | 175A | Direct burial; check termination rating |

So, what is 2 0 aluminum wire rated for in a typical installation? Unless you have special equipment, the ampacity of 2 0 aluminum wire is usually limited to 150 amps (75°C column), even if the wire itself can technically carry up to 175 amps at 90°C.

It sounds counterintuitive, but the ampacity of 2 0 aluminum wire is not just about the wire—it’s about where you connect it. NEC 110.14(C) requires you to size according to the lowest-rated termination on the circuit. Most residential and commercial distribution equipment (like breakers, lugs, and panelboards) are rated for 75°C. Even if you use a 90°C-rated insulation (such as XHHW-2 or THHN/THWN-2), you must use the 75°C ampacity column for sizing unless both ends are marked and listed for 90°C terminations—which is almost never the case below 600V.

For example, if you’re installing a 2/0 aluminum feeder to a panel with 75°C lugs, your maximum allowed ampacity is 150A. If one end of the run lands on a device with a 60°C termination (rare for 2/0, but possible with some older equipment), you must use the 60°C column—dropping your ampacity to 135A.

Always size to the equipment’s lowest temperature rating unless a code exception applies.

For more on this, see the detailed discussion on termination ratings and their impact on conductor sizing at IAEI Magazine.

Imagine you’re running several 2/0 aluminum wires in a conduit through a hot attic, or you’re bundling more than three current-carrying conductors in a raceway. Now, you must apply derating factors as required by NEC 310.15(B)(1) (ambient temperature) and 310.15(C)(1) (number of conductors).

Derating can quickly reduce the usable ampacity of 2/0 aluminum wire amps, so it’s critical to check these conditions for every installation. The NEC requires you to use the lowest resulting ampacity after all adjustments, and to ensure your overcurrent protection does not exceed that value (reference).

To sum up, the 2 0 awg aluminum wire ampacity you can actually use is often less than the theoretical maximum—and what is 2 0 aluminum wire rated for on paper may be different from what you’re allowed to use in practice. Always check your terminations and conditions of use before finalizing your wire size. Up next: step-by-step sizing examples that show how these rules play out on real projects.

Ever get stuck wondering if your 2/0 aluminum wire choice really meets code—or if you’ll run into an inspector’s red pen? Let’s walk through three real-world scenarios that demystify the process. By following these step-by-step examples, you’ll see exactly how to size a 2 0 feeder, apply derating for tough environments, and make the right call on overcurrent protection. Whether you’re planning a 150 amp ser cable run, a complex subpanel feed, or a 2 0 aluminum service wire upgrade, these samples model the logic pros use for safe, code-compliant installs.

| Step | Value/Factor |

|---|---|

| Base Ampacity (75°C) | 150A |

| Continuous Load Rule | 125% (if applicable) |

| Adjustment Factors | None |

| Final Ampacity | 150A |

Derating from the 90°C column is allowed, but final ampacity must not exceed the 75°C column when lugs are 75°C (NEC 110.14(C)).

| Step | Value/Factor |

|---|---|

| Base Ampacity (75°C) | 150A |

| Ambient Correction | × 0.88 = 132A |

| Conductor Count | × 0.80 = 105.6A |

| Final Ampacity | 105.6A |

Derating for both high ambient and multiple conductors can quickly reduce usable ampacity—always check these factors for your 2/0 service wire and 2 0 triplex runs.

| Step | Value/Factor |

|---|---|

| Base Ampacity (75°C) | 150A |

| Continuous Load Rule | Apply 125% if needed |

| Adjustment Factors | Typically none for open-air SE cable |

| Final Ampacity | 150A |

For residential service entrance, 2/0 aluminum is the standard for 150A panels; always confirm calculated load and equipment ratings for your 2/0 service wire or 2 0 triplex installation.

These examples show that while code tables provide a starting point, actual wire sizing for 2 0 ser, 2/0 service wire, and 2 0 feeder runs must account for every detail—termination ratings, continuous loads, ambient conditions, and conductor count. Always double-check these variables before finalizing your cable selection or ordering a 150 amp service entrance cable. In the next section, we’ll dive deeper into the metallurgy and material science that make modern aluminum wire safe and reliable for these demanding applications.

When you hear about modern 2/0 aluminum wire, you’re really talking about conductors made from 8000-series aluminum alloys. But why does this matter for your next project? In the past, older aluminum alloys (like AA-1350) caused headaches—loose connections, excessive creep, and even fire hazards. Today’s 8000 series, engineered with small amounts of iron, silicon, copper, and manganese, delivers a blend of strength, flexibility, and conductivity that’s purpose-built for building wire. These improvements mean your 2/0 cable diameter stays manageable, your terminations stay tight, and your installations last longer—even in tough environments. In fact, the 8000 series alloys are now the only solid or stranded aluminum conductors permitted for building wire by the NEC, meeting ASTM B800 and UL standards.

Wondering why the diameter of 2/0 wire is larger for aluminum than copper? It comes down to conductivity. Aluminum offers about 61% the conductivity of copper, so to carry the same current, you need a larger cross-sectional area. For example, a 2/0 awg aluminum wire typically has a diameter of about 0.364 inches, while the copper equivalent is smaller. This means a 2/0 aluminum wire diameter is bigger, but the wire is still much lighter—roughly half the weight of copper for the same ampacity (see comparison).

| Property | 2/0 Aluminum | 2/0 Copper |

|---|---|---|

| Conductivity (% IACS) | 61% | 100% |

| Weight (per 1,000 ft) | ~194 lb | ~320 lb |

| Diameter (conductor only) | 0.364 in | 0.364 in |

| Typical Cross-Section (mm2) | ~67.4 | ~67.4 |

| Standard (ASTM) | B800 (8000 series) | B3 (soft copper) |

So, when selecting a 2/0 aluminum wire, you gain significant weight and cost savings. And if you’re looking for the metric equivalent, 2 0 awg a mm2 is approximately 67.4 mm2—a key spec for international projects or cross-referencing global standards.

Imagine your wire connections loosening over time—sounds risky, right? This is where the material science of 8000-series alloys really matters. Aluminum expands more than copper with temperature changes and can slowly deform (creep) under sustained pressure. The 8000 series dramatically reduces creep compared to legacy aluminum, making terminations more stable over decades. Still, it’s important to use the right connectors and torque specs, as recommended by UL and manufacturer guidelines. Proper installation, periodic inspection, and re-torquing can help keep your 2/0 aluminum wire joints safe and reliable for the life of the system.

Regular inspection and re-torquing of aluminum wire terminations are key practices for long-term safety and reliability—don’t skip this step in your maintenance plan.

By understanding the material advances behind 2/0 aluminum wire, you’ll make better choices for your next installation—balancing performance, safety, and cost. Up next, we’ll cover code-compliant terminations and the best practices that keep your connections trouble-free for years to come.

When you’re working with 2/0 awg aluminum wire, the most common point of failure isn’t the cable itself—it’s the termination. Sounds complex? It doesn’t have to be. By following proven code-compliant methods, you can ensure your 2/0 electrical cable connections are safe, reliable, and inspection-ready for years to come. Let’s break down the essential steps and choices, from lug selection to torque, antioxidant use, and inspection tips.

Imagine landing your 2/0 xhhw aluminum wire in a panelboard or disconnect. The connector you choose is critical. Most modern 2/0 aluminum wire terminations use dual-rated AL7CU or AL9CU lugs, which are approved for both aluminum and copper conductors. These lugs are typically made from tin-plated aluminum alloys and are listed to UL 486A-486B standards for safety and performance (reference).

| Wire Type | Lug Type | Torque Range (in-lbs) | Verification |

|---|---|---|---|

| 2/0 XHHW-2 | AL7CU/AL9CU Mechanical or Compression | 180 (typical for mechanical, per manufacturer) | Check data sheet/label |

| 2/0 USE-2 | AL7CU/AL9CU Mechanical or Compression | 180 (mechanical); see compression die chart | Check data sheet/label |

*Always refer to the equipment label or manufacturer’s data sheet for exact torque values and approved lug types. If the label is missing, consult UL 486A-486B or the product documentation (example torque chart).

Ever wonder why some connections fail even with the right lug? It’s usually a workmanship issue—especially improper torque or missing anti-oxidant compound. NEC 110.14 and UL 486A-486B require that you torque connections to the manufacturer’s specification, not just “hand tight.” Over-tightening can be just as risky as under-tightening, potentially damaging both the lug and the conductor.

Torque to the label, not memory—document the reading.

Imagine the frustration of a failed inspection because of a missed detail. To avoid setbacks, here’s what inspectors look for on 2/0 electrical cable terminations:

Remember, the diameter of 2/0 wire with insulation (such as 2/0 xhhw aluminum wire) will vary by insulation type—so always verify that your lugs and raceway have enough room for the full cable diameter, not just the bare conductor.

By mastering these termination best practices, you’ll ensure your 2/0 aluminum wire installations are safe, code-compliant, and trouble-free for years to come. Next, we’ll explore how to choose the right cable assembly for different service entrance and underground applications.

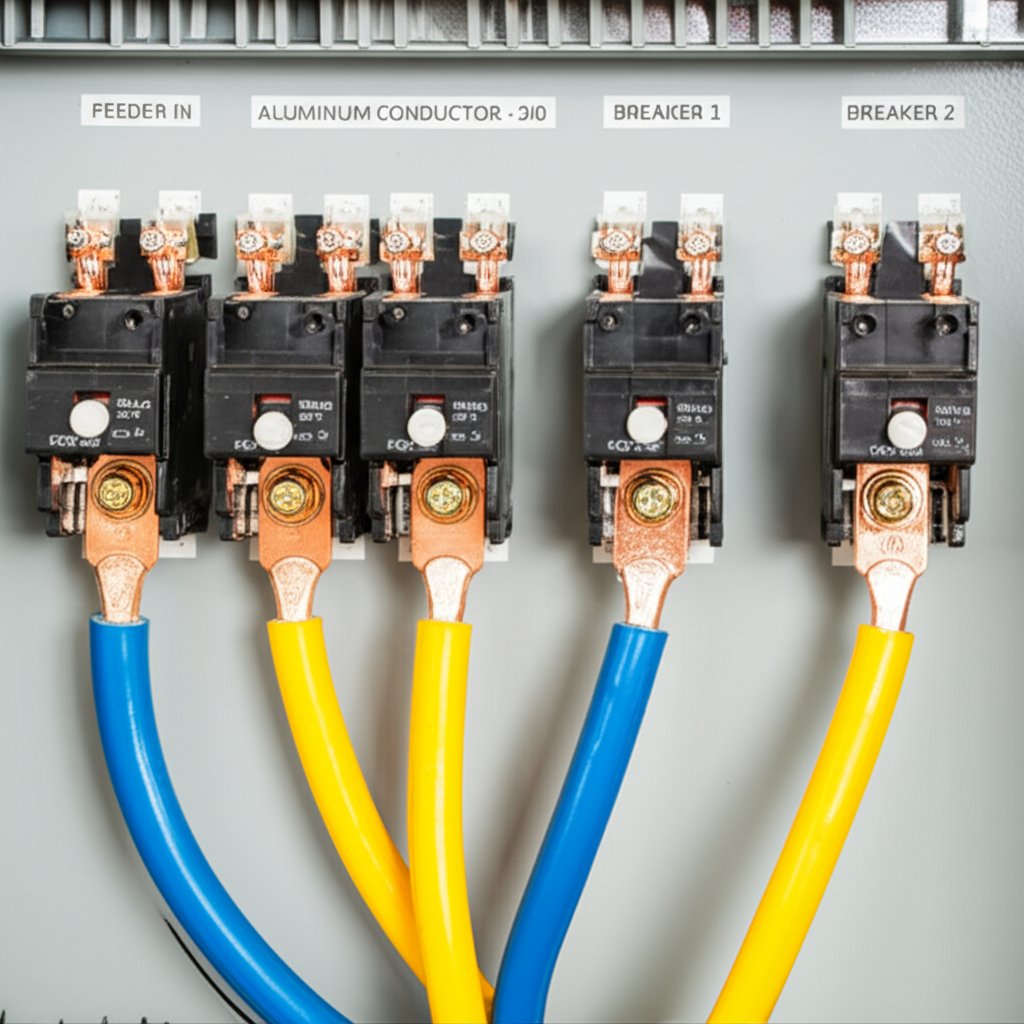

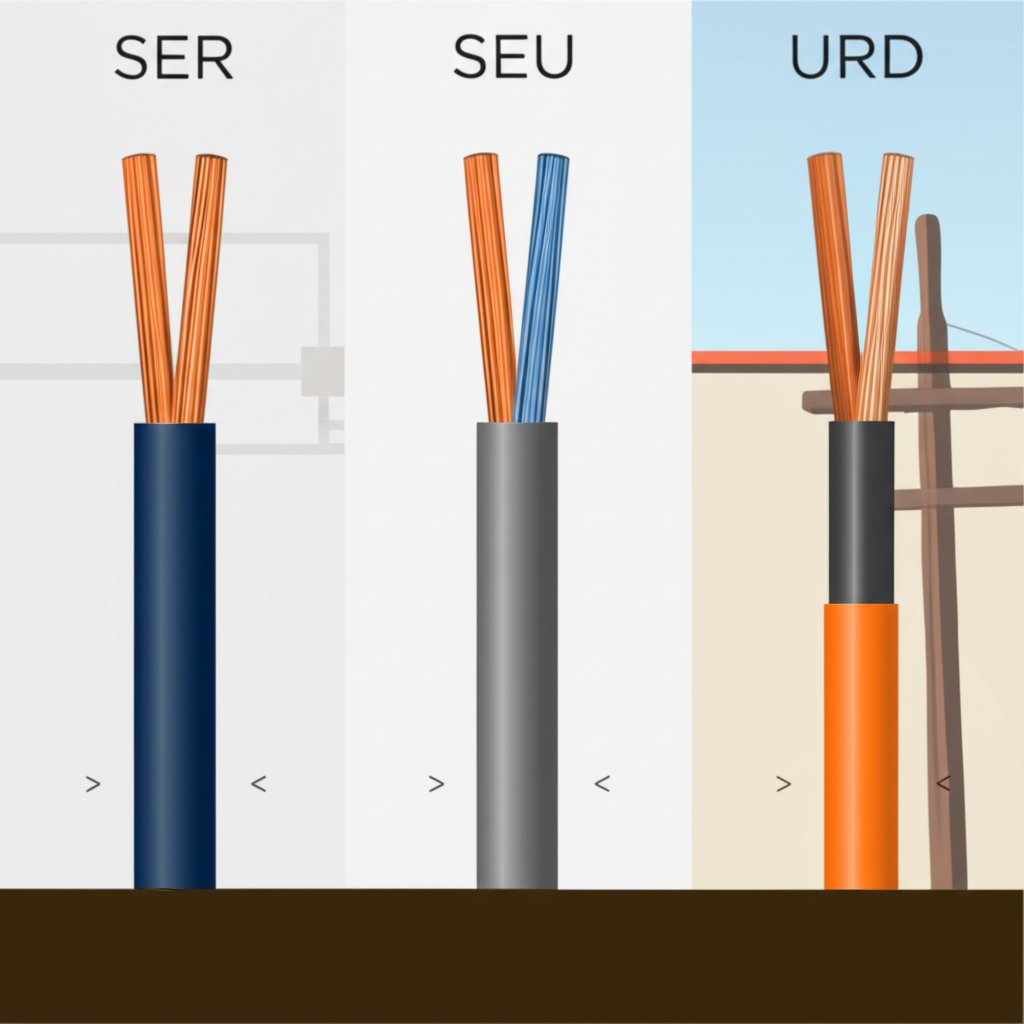

Ever stared at a wall of cables and wondered, “Which 2/0 aluminum assembly is right for my project?” The answer depends on where you’re running the wire and what the installation demands. Let’s break down the three most common choices for 2/0 aluminum service and feeder cables:

| Assembly | Jacket/Insulation | Direct Burial? | Typical Ampacity | Common Use Cases |

|---|---|---|---|---|

| 2/0 SER | PVC jacket, XHHW-2 or THHN/THWN-2 insulation | No | 150A (75°C), per NEC 310.16 | Indoor/outdoor feeders, subpanels above ground |

| 2/0 SEU | PVC jacket, XHHW-2 or THHN/THWN-2 insulation | No | 150A (75°C) | Main service entrance (meter to main panel) |

| 2/0-2/0-2/0 URD | XLPE insulation, no overall jacket | Yes | 245A (direct burial), 180A (in-duct) | Underground lateral, direct burial wire |

| USE-2 Single | XLPE insulation, sunlight/moisture resistant | Yes | 175A (90°C), 150A (75°C) | Underground service, direct burial |

Sounds complex? Here’s the simple version: SER cable has both a neutral and a ground, so it’s perfect for subpanel feeders where neutral and ground must be separated (per NEC 250). SEU only has a neutral, so it can’t be used to feed subpanels—just up to the main disconnect, where neutral and ground are bonded. For underground runs, 2/0-2/0-2/0 aluminum wire triplex URD cables typically include two phase conductors and a neutral, but not a ground; you must provide a separate equipment grounding conductor if required by code.

Imagine you’re running a lateral from a utility transformer to a home—should you use conduit or direct burial? Here’s how to decide:

For example, a 2/0 aluminum wire direct burial installation using 2/0-2/0-2/0 URD can handle up to 245A per manufacturer data, but always check local code and utility requirements.

Service entrance conductors (like 2/0-2/0-2/0 aluminum wire) follow NEC 230 special rules, which may differ from standard feeder requirements—always verify with your local inspector.

By understanding the differences between 2/0 ser cable, SEU, and 2/0 urd aluminum wire, you can make confident, code-compliant choices for every environment—from subpanels to direct burial wire. Next, we’ll cover procurement, cost, and logistics tips to help you order and handle these cables with confidence.

When you’re ready to buy 2/0 aluminum wire, you’ll notice suppliers offer it by the foot, in standard put-ups, or as full reels. Sounds complex? Not really—here’s how it works in practice:

Lead times for common constructions like 2/0 underground wire or 2/0 ser aluminum wire are typically short for stock items, but special colors, long lengths, or parallel pulls may require extra days for processing. Always confirm availability and delivery schedules before finalizing your order.

Imagine receiving your cable only to find it’s the wrong type or missing a required certification. To avoid costly delays, always request a detailed specification sheet and supporting documents. Here’s a checklist you can use for every 2/0 aluminum wire order:

Requesting these documents up front helps prevent change orders and ensures your 2/0 triplex aluminum wire or 2/0 underground wire meets both project specs and inspection requirements.

Wondering why 2 0 wire aluminum is so popular for large feeders? The answer is simple: cost and weight. Aluminum conductors are much lighter and less expensive than copper, especially for long runs or high-ampacity circuits. But it’s not just about price—handling and shipping logistics matter too.

| Wire Type | Typical Cost/ft* | Weight/ft (lbs) | Common Applications |

|---|---|---|---|

| 2/0 Aluminum | $1.20–$2.00 | ~0.16 | Feeders, service entrance, direct burial (URD) |

| 2/0 Copper | $5.00–$8.00 | ~0.32 | High-reliability feeders, short runs, harsh environments |

| 4/0 Aluminum | $2.20–$3.50 | ~0.25 | 200A services, long feeders, utility laterals |

*Prices are approximate and fluctuate daily with commodity markets. For reference, see retail listings for 4 0 4 0 2 0 aluminum wire home depot, 4/0 aluminum wire 200 amp service home depot, or supplier price sheets for 3/0 aluminum wire price comparisons.

Aluminum’s lighter weight means easier handling, lower shipping costs, and less strain during installation. For example, a 1,000-foot reel of 2/0 aluminum weighs about 160 lbs, while copper would be double that—saving you time and labor, especially on large jobs.

Retailers and distributors may have minimum cut lengths and special order policies. Pricing is commodity-linked—always check for up-to-date quotes before ordering.

By following these procurement and logistics best practices, you’ll avoid costly surprises and keep your 2/0 aluminum wire project on track. Next, we’ll wrap up with field-proven case studies and job aids that help you turn this knowledge into action.

Ever wonder what separates a smooth inspection from a frustrating rework on your 2/0 aluminum wire job? It often comes down to real-world details—like following the right checklist, documenting your torque, and understanding how code rules play out on site. Let’s look at two anonymized, field-tested case studies and share practical tools you can use on your next project.

Imagine you’re tasked with upgrading a residential subpanel using 2/0 ser cable. The feeder runs from the main service entrance panel to a detached garage. Here’s how the pro handled it:

This approach not only ensured the 2/0 ser installation was safe and code-compliant, but also saved time by anticipating exactly what the inspector would check.

Now, picture a utility lateral supplying power to a new outbuilding using 2/0 urd cable. The contractor’s steps:

By verifying that the 2 0 2 0 2 0 urd cable was properly rated and applying the right adjustments, the job avoided costly callbacks and ensured long-term reliability.

Want to make your next 2/0 aluminum wire installation as smooth as these cases? Use these job aids to avoid common pitfalls:

| Pre-Installation | |

| ✔ | Verify cable type and ratings (SER, URD, USE-2, etc.) |

| ✔ | Check equipment lug compatibility (AL7CU/AL9CU, size, temp rating) |

| ✔ | Review NEC ampacity and all derating factors |

| Installation | |

| ✔ | Wire brush conductors and apply antioxidant (if required) |

| ✔ | Torque connections to manufacturer specs and log readings |

| ✔ | Separate neutral and ground at subpanels (SER only) |

| ✔ | Confirm burial depth for direct burial (2 0 2 0 2 0 urd aluminum wire) |

| Post-Installation | |

| ✔ | Label circuits and document all test results |

| ✔ | Prepare inspection packet (spec sheets, torque log, burial photos) |

Key takeaway: Always size your service entrance cable 2 0 or 2 0 2 0 2 0 urd to the lowest-rated termination, and keep a torque log for every connection—these are the details that pass inspection and prevent callbacks.

Armed with these field-proven strategies, checklists, and templates, you’re ready to turn code knowledge into real-world project success—saving time, passing inspections, and building safer electrical systems every time.

2/0 aluminum wire is commonly used for high-current electrical applications such as service entrance feeders, subpanel feeders, underground residential distribution (URD) laterals, and large branch circuits. It is chosen for its balance of ampacity, lighter weight, and cost savings compared to copper, making it ideal for residential, commercial, and light industrial projects.

The ampacity of 2/0 aluminum wire depends on insulation type, installation, and termination temperature ratings. Typically, it is rated for 150 amps when using 75°C-rated terminations, which is standard for most electrical panels and equipment. Under specific conditions and with 90°C insulation, it can be rated up to 175 amps, but the lowest-rated termination always governs the final ampacity.

Yes, certain constructions of 2/0 aluminum wire, such as USE-2 cable and 2/0-2/0-2/0 URD triplex, are designed for direct burial. These cables have insulation and jackets that are resistant to moisture and sunlight, making them suitable for underground installations without conduit, as long as local codes and utility requirements are met.

SER cable is used for above-ground feeders and includes both a neutral and ground, making it suitable for subpanels. SEU cable is intended for main service entrance from the meter to the main panel and lacks a separate ground. URD cable, such as 2/0-2/0-2/0 aluminum wire, is used for underground laterals and is rated for direct burial, typically without an equipment ground, so a separate ground may be required.

2/0 aluminum wire offers significant cost and weight savings compared to copper, especially for long runs or high-ampacity circuits. While aluminum conductors are larger in diameter for the same ampacity, they are much lighter and easier to handle. Modern 8000-series aluminum alloys also provide improved reliability and safety for building wire applications.

บริการออนไลน์

บริการออนไลน์ 0086 136 3563 2360

0086 136 3563 2360 sales@sxalu.com

sales@sxalu.com +86 136 3563 2360

+86 136 3563 2360